What changed?

The Environmental Protection Agency (EPA) finalized the phasedown schedule (above) for hydrofluorocarbons (HFCs), which is mandated by the American Innovation and Manufacturing Act (AIM Act). There were no changes between the proposal and the final rule. The schedule still calls for a segmented reduction in HFCs produced and consumed, ending in an 85% reduction by 2036.

The finalized rule includes an allocation and trading program, which determines the amount of refrigerant that may be produced and consumed. There were no changes between the proposal and the final rule.

Who is impacted?

- Refrigerant Producers: Companies that produce, import, export, destroy, reclaim, or recycle HFCs are issued allowances by the EPA on October 1 of each year. These allowances are relative to the phasedown schedule.

- End Users: Companies that use refrigeration equipment—such as retailers, cold storage warehouses, and industrial process facilities—will feel an indirect impact because HFC refrigerant will be less common and more expensive.

We know from the recent phaseout of R-22 that this phasedown will cause refrigerant prices to rise. HFC refrigerants that are manufactured will primarily be used to service leaks in existing systems, plus HFC refrigerants are shared with other industries, such as air conditioning and foaming processing. This could impact cost and availability of refrigerants to retailers and industrial end users, meaning that budgets for repairs will need to increase.

What should retailers and other end users do?

To counteract this, Zero Zone recommends that future orders for refrigeration equipment should be switched to alternative refrigerants sooner than later, such as natural refrigerants and low-GWP HFO-based refrigerants. This will make service costs better in the long run. Plus, it will prepare end users for upcoming EPA rules that will further regulate refrigerants.

What other rules are coming?

The refrigeration industry awaits three more final EPA rules.

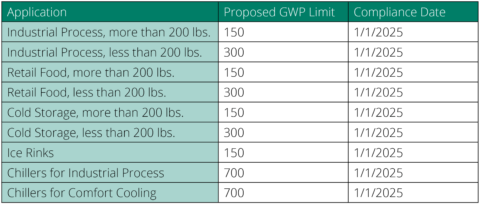

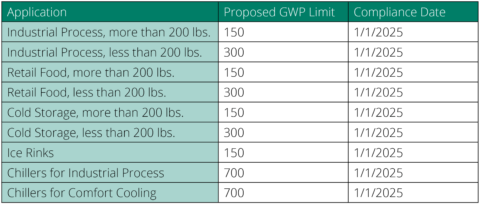

1) The EPA proposed a rule that will establish limits by 1/1/2025 on the global warming potential (GWP) of refrigerants. This rule must be finalized in October 2023. Below are the current GWP restrictions proposed.

These GWP limits will end the use refrigerants such as R-404A (GWP of 3943), R-407A (GWP of 1923), R-410A (GWP of 1924), R-448A (GWP of 1273), R-449A (GWP of 1282), and R-507 (GWP of 3985) in new equipment. Going forward, refrigeration equipment will need to use natural refrigerants, such as CO2 (GWP of 1), ammonia (GWP of 0), and HFO-based refrigerants with GWP less than the limits.

2) The refrigeration industry also awaits the release of EPA Rule 26, which will allow for the use of A2L refrigerants in commercial and industrial applications. “A2L” refers to an ASHRAE classification of refrigerants that are mildly flammable. Rule 26 would also increase the allowable R-290 (propane) charges for self-contained equipment.

3) The EPA will be updating Section 608 of the EPA Clean Air Act (CAA), which regulates handling, recovery, reclamation, and recycling of refrigerants. They are updating the rule for how service technicians can handle refrigerants and how refrigerant use is reported by store owners.

Further Reading

For more information about upcoming EPA regulations: “The National Plan for Refrigerant Regulations.”

For more information about current state regulations: “The State of Refrigerant Regulations.”

If you have questions about these regulations, please contact Zero Zone and ask to speak to our Director of Regulatory Compliance & Refrigeration Technology. If you want to learn about our offerings and plan for these regulations, contact our sales team.

Coming Soon to the Dyersville Community!

Zero Zone brings the CHILL… We design refrigeration systems that keep fresh food cold, pharmaceuticals safe, and ice rinks frozen!

Now, you can be part of our COOL Team. Zero Zone is expanding our refrigeration systems manufacturing to Dyersville, Iowa! We need enthusiastic people for our new facility and are offering competitive wages and a collaborative environment to those who want to grow with our company! Become part of a skilled labor force where variety, cross-training, and advancement opportunities are the norm (not monotonous assembly work). Whether you’re interested in management, engineering, or manufacturing positions, now is the time to take action. Come grow with us. We have Midwestern values and a genuine do-it-right-the-first-time work ethic. If you do too, see available positions and APPLY NOW at: https://www.zero-zone.com/careers/ or email careers.ia@zero-zone.com.

Zero Zone Systems Division, based in Ramsey, Minnesota, is a respected manufacturer of commercial and industrial refrigeration systems and chillers for retail food stores, cold storage, food processing, pharmaceutical/biomedical manufacturing, and ice arenas.

The Systems Division is part of Zero Zone Inc., headquartered in North Prairie, Wisconsin. From three facilities in Wisconsin, its Display Case Division has been manufacturing commercial coolers and freezers for supermarkets, grocery, convenience, dollar, and drug stores for over 60 years.

Zero Zone Systems Division designs and builds some of the finest refrigeration systems in North America from its main manufacturing facility in Ramsey, Minnesota and, now, from its new manufacturing location in Dyersville, Iowa.

Bruce Hierlmeier PE, the Director of Regulatory Compliance & Refrigeration Technology for Zero Zone, was announced as a recipient of the Richard C. Schulze Award at the 2020 Air-Conditioning, Heating, & Refrigeration Institute (AHRI) Virtual Leadership Forum. The Richard C. Schulze Award is presented at the opening session to 3 individuals whose contributions influenced both AHRI and the industry as a whole. Zero Zone is incredibly proud of Bruce Hierlmeier’s contributions to the refrigeration industry.

In the presentation, Hierlmeier was recognized for his dedication to commercial refrigeration, both through AHRI and the Commercial Refrigerator Manufacturers Association (CRMA), which later merged with AHRI. Hierlmeier was credited for being instrumental to the growth of the refrigeration sector of AHRI during his service as the inaugural chair of the Refrigeration Regulatory Committee. He contributed to major revisions as chair of the Safety Standards Committee, accomplishing those revisions in less than a year to allow the safe use of flammable, low-GWP refrigerants in refrigeration systems. Hierlmeier was also regarded as an expert in regulatory compliance whose valuable input helps others understand EPA SNAP regulations and state regulations.

Additionally, Hierlmeier served as the engineering chair and later the section chair for the AHRI Commercial Refrigeration Division after the merger with CRMA. He also served as the section chair for the compressor and condensing unit section.

Bruce Hierlmeier’s contributions to the refrigeration industry extend far beyond AHRI. Hierlmeier has been a member of the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) since 1993 and the International Institute of Ammonia Research (IIAR) since 2016. Hierlmeier has authored and contributed to sections of the ASHRAE Handbook on Refrigeration in 2014 and 2018, a handbook that is published every 4 years and drives industry requirements. For IIAR, he served as chair of the chapters 5 & 6 subcommittees for the CO2 Handbook. He has also authored or professionally commented on sections within UL Standard 471, NSF Standard 7, DOE regulations for commercial refrigeration, and CARB regulations.

Hierlmeier’s background includes an MBA from UW-Milwaukee in 1993 and a BS in Mechanical Engineering from UW-Platteville in 1983. He has earned and maintained his professional engineer (PE) license since 1988, and he has belonged to the Order of the Engineer since 1983. He also holds a patent for an innovative air duct design that assures uniform product temperature inside Zero Zone Crystal Merchandiser™ coolers.

After being selected for the 2020 AHRI Richard C. Schulze Award, Bruce Hierlmeier was approached by his peers, who complimented his efforts and congratulated him for winning the award. Everyone at Zero Zone extends the same enthusiasm and appreciation.

Zero Zone is incredibly proud of the hard work and expertise that John Collins, Industrial Sales Manager – East for Zero Zone, displayed in researching, writing, and presenting his technical paper, “Analysis of Package Chiller Systems – Comparison of Natural (NH3 & CO2) and HFC Refrigerants.” He presented it at the International Institute for Ammonia Research (IIAR) 2020 Virtual Conference, and he was awarded the well-deserved IIAR 2020 Award for Presentation Excellence – Food/Retail Refrigeration.

Collins thoroughly analyzed the data from 3 ice arena chillers that used different refrigerants in order to demonstrate statistically and strategically the advantages afforded by each refrigerant. Collins applied his study by presenting his findings as practical criteria that can help buyers choose a refrigerant that matches their goals and priorities for safety, cost, sustainability, serviceability, and more.

Collins also thanks his colleagues, Global Refrigeration Manager Masood Ali and Systems Engineering Manager Adam Ciesielski, for their insight and assistance in developing and reviewing the manuscript, and Zero Zone gratefully acknowledges their collaboration.

Click here to read the full paper for yourself: “Analysis of Package Chiller Systems – Comparison of Natural (NH3 & CO2) and HFC Refrigerants”

Not even refrigeration regulations are simple after 2020. Refrigerant regulations are changing, and getting new refrigeration equipment is complicated. This adds more challenges to stores, cold storage warehouses, pharmaceutical plants, and more.

Here is the brief summary of recent refrigerant regulations. The United States Environmental Protection Agency (EPA) issued SNAP Rules 20 and 21 in 2015 and 2016 to eliminate the use of refrigerants with high global warming potential (GWP), but those rules were vacated by the D.C. circuit court in 2017 and 2019. Since then, individual states have taken responsibility for issuing their own regulations. So far, most state regulations target the same high GWP refrigerants, but they have different effective dates and even define the effective dates differently. This creates a challenge for both buyers and manufacturers who need to know whether their new equipment will be compliant.

Zero Zone wants to help by providing the effective dates and a map so it is clear whether your state has any regulations. Check out our article about The State of Refrigerant Regulations. Please note that we recommend that our customers contact their state’s environmental regulatory department to clarify the nuances, but our research will be a valuable starting point.

The California Air Resources Board (CARB) has officially published details about the California Cooling Act, which will take effect on January 1, 2019. The Act, which is based on vacated EPA SNAP Rule 20, prohibits HFC refrigerants with high global warming potential (GWP)—such as R-404A and R-507A—for supermarket systems, condensing units, and self-contained units.

The California Cooling Act affects new and retrofit equipment. Manufacturers cannot sell equipment using prohibited refrigerants that are manufactured after January 1, 2019.

CARB Definition for New Refrigeration Equipment:

- Any refrigeration equipment that is first installed using new or used components; or

- Any refrigeration equipment that is modified such that it is:

- Expanded after the date at which this subarticle becomes effective, to handle an expanded cooling load by the addition of components in which the capacity of the system is increased, including refrigerant lines, evaporators, compressors, condensers, and other components; or

- Replaced or cumulatively replaced after the date at which this subarticle becomes effective, such that the capital cost of replacing or cumulatively replacing components exceeds 50 percent of the capital cost of replacing the entire refrigeration system.

If the retailer or engineer is unsure whether the work will classify as a new system, they should contact the Refrigerant Management Program Hotline at 916-324-2517 or rmp@arb.ca.gov.

Additional Reading:

Refer to the following for more information about California’s regulations or the EPA regulations that affect the rest of the country:

For further information, contact Zero Zone at 800-247-4496 and ask for our Department of Regulatory Compliance and Refrigeration Technology. This message is informational only, and customers should review the new regulations fully to ensure compliance.

Three Zero Zone engineers received special recognition from ASHRAE for their extensive contributions to the 2018 ASHRAE Handbook (from left to right): Mike Chieffo, Compliance and Engineering Analyst; Bruce Hierlmeier PE, Director of Regulatory Compliance and Refrigeration Technology; Carl Roberts, Engineering Lab Manager. Hierlmeier and Roberts have participated for over 20 years, and Chieffo joined for his first effort. These three men account for the largest representation from an individual refrigeration manufacturer.

Their efforts focused on adding technical information and omitting obsolete data from two chapters: “Retail Food Store Refrigeration and Equipment” and “Food Service and General Commercial Refrigeration Equipment.” Their additions reflected recent technology developments, new regulations, and the shifting mindset of industry leaders, with an emphasis on sustainability and energy efficiency. Topics included design enhancements and new refrigerants, such as high glide refrigerants, propane, and CO2—particularly in transcritical mode.

Zero Zone is proud of their combined efforts for the 2018 ASHRAE Handbook, which is used as a reference by refrigeration engineers and government agencies that write regulations.

It doesn’t feel like Autumn in Wisconsin yet, however, Zero Zone is already looking forward to The Big Chill…an article in the August issue of Grocery Headquarters magazine, that is! “The Big Chill” features the Zero Zone Highlight™ Merchandiser and Reveal Merchandiser™, as well as Zero Zone’s Marketing & Advertising Manager, Carl Petersen, who comments about developments in keeping food cold, fresh, and safe.

Zero Zone is proud to announce we have partnered with Honeywell and Festival Foods to design and install equipment for use with R448A refrigerant instead of the previously used R404A refrigerant. Festival Foods made this decision after much collaboration with John’s Refrigeration, Honeywell, and Zero Zone employees. The R448A system will give Festival Foods what they were looking for in terms of performance and regulatory needs in their stores, including but not limited to, a lower GWP, easy serviceability, and energy efficiency. We look forward to working with Festival Foods, Honeywell, and John’s Refrigeration on many more projects!

To read the article published in Cooling Post, click on the following link Festival Foods opts for R448A

The American Cancer Society’s mission is to help people who are braving cancer. On Friday, June 23rd Zero Zone assisted with their mission by raising funds and walking in our local American Cancer Society Relay For Life event. We are extremely humble and proud to say that we have so far raised over $3,900! Saving lives from cancer starts one team, one participant, one dollar at a time. If you are interested in fighting back with us by making a donation, please go to this link by Saturday, July 15th and click on Donate: http://main.acsevents.org/site/TR/?fr_id=80166&pg=team&team_id=2160886.