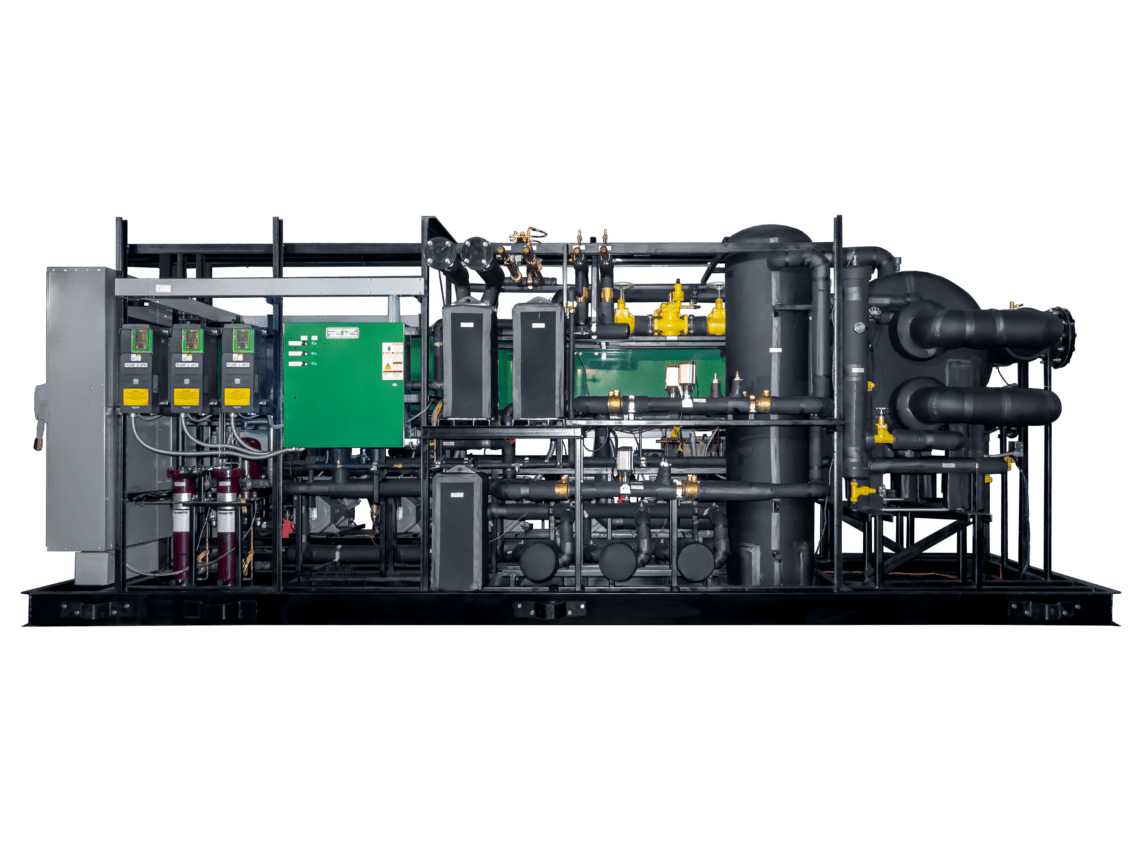

Overview of the Industrial Chiller

Custom chiller packages for ice arenas and other large capacity applications are indirect refrigeration systems that utilize propylene or ethylene glycol process fluids. These chillers use multiple smaller compressors, allowing the system to adjust smoothly and efficiently to changing loads.

Key Features of the Industrial Chiller

An industrial refrigeration chiller system is a large-scale cooling solution for precise temperature control in industrial applications. Key components like compressors, condensers, evaporators, and refrigerant fluid ensure effective heat exchange. Explore all features below.

Indoor or Outdoor Configuration

Zero Zone Chiller Systems offer the flexibility to be installed either indoors or outdoors, adapting to diverse spatial requirements and environmental conditions.

Optional Pump and Heat Exchangers

The systems provide customization options with the inclusion of optional pumps and heat exchangers, allowing tailored configurations to meet specific operational needs.

Single or Multiple Chiller Circuits

Designed for versatility, these chiller systems can be configured with either a single chiller circuit or multiple circuits, accommodating varying cooling demands and operational scenarios.

Self-Contained or Split Refrigeration System

The chiller systems feature self-contained or split refrigeration units, simplifying installation and minimizing external dependencies for efficient and autonomous operation.

Diverse Refrigerant Options

Zero Zone offers a range of refrigerant choices, including HFC, CO2, or ammonia. This flexibility enables users to select the most suitable refrigerant based on environmental considerations and system requirements.

Condenser Cooling Method Options

The chiller systems support different condenser cooling methods, such as air-cooled, evaporative-cooled, or water-cooled configurations. This adaptability caters to specific cooling needs and environmental conditions.

PLC Controls with Internet Remote Access

Equipped with advanced Programmable Logic Controller (PLC) controls, these systems provide precise operational management. The inclusion of Internet remote access enhances troubleshooting capabilities, allowing users to control and supervise the system for increased efficiency and responsiveness.

Options Table

Enhance your experience with a range of optional features tailored to your unique needs.

Feature |

Options |

|---|---|

Refrigerant |

R-134A,

R-404A,

R-407A,

R-407C,

R-448A,

R-449A,

R-507,

R-513A,

Genesys™

Ammonia Systems (R-717),

Genesys™ CO2 Systems (R-744) |

Compressors |

Reciprocating or Screw |

Control Systems |

Copeland,

Danfoss,

Micro Thermo,

RDM,

PLC (Allen Bradley) |

Receiver |

Horizontal & Vertical Receiver(s) |

Model

Coldloop Ice Arena Chiller Systems

Zero Zone provides tailored refrigeration solutions for new or existing facilities, ensuring optimal efficiency. The design, incorporating multiple compressors, minimizes operational costs by aligning with the load.

In applications like ice rinks, this approach enhances freezing efficiency. Customer’s value Zero Zone Refrigeration Chiller Systems for their reliable performance and exceptional energy efficiency.

Custom Engineered for You

Customers can conveniently modify their ice rink refrigeration systems to meet their exact specifications. There are several optional features Zero Zone offers, including:

- Indoor or outdoor configuration

- Air-cooled, evaporative-cooled, or water-cooled condenser

- PLC controls with Internet remote access

- Shell & tube or plate heat exchangers

- Glycol or brine secondary coolant

- Environmentally friendly chiller options

- CO2 refrigerant

- Ammonia refrigerant

Structure & Sizing Options

Explore our Structure & Sizing Options for tailored solutions to meet your specific needs.

Variable speed compressors

These compressors can adjust their speed based on the cooling demand, optimizing energy efficiency and performance.

Mechanical Unloading

This feature allows the chiller system to adjust its capacity by unloading or loading compressors as needed, enhancing energy efficiency during varying cooling demands.

EC Fan Condensing Motors

Electronically Commutated (EC) fan motors offer energy-efficient and precise control of condenser fan speeds, contributing to overall system efficiency.

VFD Condenser Fan Motors

Variable Frequency Drive (VFD) condenser fan motors allow for adjustable fan speeds, providing flexibility in responding to different heat dissipation requirements.

Welded Steel Pipe

The use of welded steel pipes ensures durability and reliability in the chiller system's piping, minimizing the risk of leaks or structural issues.

Heat Reclaim

This feature enables the recovery of waste heat from the chiller system, offering additional energy savings by repurposing heat for other applications, such as space heating.

Resources

Brochures

Product Sheets

Case Studies

White Papers

Technical Papers

Manuals