What changed?

The Environmental Protection Agency (EPA) finalized the phasedown schedule (above) for hydrofluorocarbons (HFCs), which is mandated by the American Innovation and Manufacturing Act (AIM Act). There were no changes between the proposal and the final rule. The schedule still calls for a segmented reduction in HFCs produced and consumed, ending in an 85% reduction by 2036.

The finalized rule includes an allocation and trading program, which determines the amount of refrigerant that may be produced and consumed. There were no changes between the proposal and the final rule.

Who is impacted by the AIM Act?

- Refrigerant Producers: Companies that produce, import, export, destroy, reclaim, or recycle HFCs are issued allowances by the EPA on October 1 of each year. These allowances are relative to the phasedown schedule.

- End Users: Companies that use refrigeration equipment—such as retailers, cold storage warehouses, and industrial process facilities—will feel an indirect impact because HFC refrigerant will be less common and more expensive.

We know from the recent phaseout of R-22 that this phasedown will cause refrigerant prices to rise. HFC refrigerants that are manufactured will primarily be used to service leaks in existing systems, plus HFC refrigerants are shared with other industries, such as air conditioning and foaming processing. This could impact cost and availability of refrigerants to retailers and industrial end users, meaning that budgets for repairs will need to increase.

What should retailers and other end users do?

To counteract this, Zero Zone recommends that future orders for refrigeration equipment should be switched to alternative refrigerants sooner than later, such as natural refrigerants and low-GWP HFO-based refrigerants. This will make service costs better in the long run. Plus, it will prepare end users for upcoming EPA rules that will further regulate refrigerants.

What other rules are coming?

The refrigeration industry awaits three more final EPA rules.

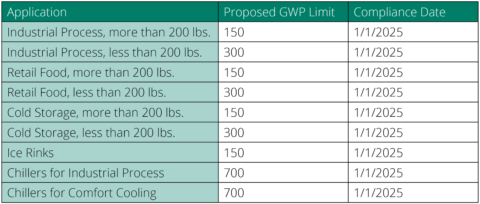

1) The EPA proposed a rule that will establish limits by 1/1/2025 on the global warming potential (GWP) of refrigerants. This rule must be finalized in October 2023. Below are the current GWP restrictions proposed.

These GWP limits will end the use refrigerants such as R-404A (GWP of 3943), R-407A (GWP of 1923), R-410A (GWP of 1924), R-448A (GWP of 1273), R-449A (GWP of 1282), and R-507 (GWP of 3985) in new equipment. Going forward, refrigeration equipment will need to use natural refrigerants, such as CO2 (GWP of 1), ammonia (GWP of 0), and HFO-based refrigerants with GWP less than the limits.

2) The refrigeration industry also awaits the release of EPA Rule 26, which will allow for the use of A2L refrigerants in commercial and industrial applications. “A2L” refers to an ASHRAE classification of refrigerants that are mildly flammable. Rule 26 would also increase the allowable R-290 (propane) charges for self-contained equipment.

3) The EPA will be updating Section 608 of the EPA Clean Air Act (CAA), which regulates handling, recovery, reclamation, and recycling of refrigerants. They are updating the rule for how service technicians can handle refrigerants and how refrigerant use is reported by store owners.

Further Reading

For more information about upcoming EPA regulations: “The National Plan for Refrigerant Regulations.”

For more information about current state regulations: “The State of Refrigerant Regulations.”

If you have questions about these regulations, please contact Zero Zone and ask to speak to our Director of Regulatory Compliance & Refrigeration Technology. If you want to learn about our offerings and plan for these regulations, contact our sales team.

Refrigeration Load Requirements & Challenges

Private label juice manufacturer Citrus Systems, Inc. specializes in pasteurizing an extensive line of juices and fruit drinks. The business provides juice to local dairies, grocery stores, and institutional customers. Their success and future contracts led them to build a new facility that is twice as large as their previous location. Consequently, this expansion presented several challenges for their refrigeration needs.

Large Capacity Needed

To accommodate their increased production, Citrus Systems required:

- 2 pasteurizers

- 6 packaging lines

- 18 blending and storage vessels

- Over 560,000 cubic feet of storage

- Doubled square footage from the previous facility

- A system that follows precise HACCP food safety guidelines from the FDA

The Zero Zone Refrigeration Solution

To meet these demands, Zero Zone provided three refrigeration systems:

- A low temperature rack offering 82 tons of cooling at -23°F

- A medium temperature rack providing 124 tons of cooling at +20°F

- A 4-circuit chiller delivering 240 tons of cooling at +18°F

Additionally, Zero Zone designed and built a package rack system to be installed on-site. To ensure food safety, the system includes remote monitoring and diagnostics.

The refrigeration systems are designed to provide trouble-free, energy-efficient operation for Citrus Systems’ production process. Zero Zone incorporated features and technology tailored to the needs of pasteurization plants, such as multiple chilling circuits, industrial PLC controls, and evaporative condensing with variable speed fan control. Furthermore, a heat reclaim system off the compressor discharge circuit reduces both electric and natural gas demand by repurposing heat for hot water used throughout the production facility.

Guaranteeing that the system always maintains the correct temperature is essential for Citrus Systems’ HACCP program. To monitor operations and communicate any alarm conditions, Citrus Systems implemented a remote diagnostics system connected to the refrigeration equipment. Consistency and dependability are crucial in the pasteurization and food processing industries to protect the quality of the final product.

A Satisfied Customer

Thomas E. Boehland, founder and president of Citrus Systems, takes great satisfaction in how everything came together, describing the equipment as “a work of art.” He praised the Zero Zone team: “You can tell that there is a lot of pride in what they put together. It isn’t just a bunch of refrigeration components cobbled together on-site to get the job done. It’s a nice package, and you can tell just by looking at it. The factory people take pride in it and even sign off on the equipment with each individual person putting their names to it. You don’t see that very often these days.” Boehland concluded by saying, “I’ve put my faith in Zero Zone to do what we need to be done.”

Contact our sales team to start on your next refrigeration journey.

Read more in the full case study: “An Industrial Work of Art.”

At Zero Zone, the gold standard is a crystal: a Crystal Merchandiser®. These reach-in display cases have served retailers across every application: beverage, dairy, deli, meat, produce, and frozen food. To understand why, let’s look at 5 reasons that retailers love the Crystal Merchandiser®.

#1: Excellent Energy Efficiency

Up to 84% less energy than open multi-decks

Up to 45% less energy than other reach-in coolers

We know what matters most of all, and that is profit and cost. The Crystal Merchandiser® is the clear choice for maximizing profit while minimizing operating cost. These cases were engineered for excellent energy efficiency, especially against open multi-deck cases (up to 84% less energy) and even against other reach-in coolers (up to 45% less energy).

A retailer’s vice president of facilities and equipment said, “The energy savings are what really make you stop and say, ‘I need to take a serious look at this’. Then you start getting into things that become more apparent once you have the cases in—the comfort in the aisle, how great the product labels appear from the LED lighting—all of those subsequent advantages.”

#2: 74″ Tall CoolView® Doors

Not only do Zero Zone cases have excellent energy efficiency, but they are energy efficient while also having some of the largest doors in the industry. These 74″ tall doors open up the Crystal Merchandiser® to shoppers, making it easy for them to see products and make their selection.

Our 30″ wide CoolView® Illusion® doors for our low-temperature cases are known for glass that goes all the way to the edge of the door, giving the impression that the case is open even when the door is closed. The effect is most dramatic for a lineup of cases where the aisle will look like a wall of enticing product. Shoppers may be under the illusion that the door is not even there.

Crystal Merchandiser® Low Temp RVLC30 with CoolView® Illusion® Doors

The medium-temperature cases use CoolView® Ultra™ doors, which are notable for their broad display and slender frames. These are available as either 24″ wide French-swing doors or as 30″ wide single-swing doors. This lets retailers pick the right door to fit their merchandising strategy and store planogram.

#3: More Facings & More Packout

With taller doors comes increased product facings: up to 35% more facings than other display cases. In addition, the Crystal Merchandiser® also offers more merchandising space with 6 full shelves, which means up to 25% more packout. “We are able to get an entire case of 6-packs out as well as 3 12-packs on each shelf,” a liquor store manager noted. “You might think that with 6 shelves instead of 5, it might be more difficult for the consumer to pull product off of the shelving, but it has actually been easier.”

For even more space, take a look at the Zero Zone Deep cases, which allows you to fit 4 30-packs of 12 oz. cans in the bottom basket.

Crystal Merchandiser® Medium Temp RVMC30D Deep Case

Extra space can be valuable in any department in a store. Another store manager said, “In the yogurt section, with the old open cases that weren’t self-feeding, you would have to restock after you sold 6 units—or pull it all forward. But in this situation, you fill it once, you go back in mid-day and refill it. I mean, the labor savings is astronomical—about an hour and a half a day. That’s one of the ways we’ve been able to cut some inefficiencies.”

#4: More Efficient Use of Floor Space

Part of the genius of the Crystal Merchandiser® is that in addition to offering more facings and packout, the case actually uses less floor space within stores. The Crystal Merchandiser® is only 39 1/2″ from the back of the case to the front of the door handle. It is up to 7″ narrower than multi-deck cases. This allows retailers to use that space elsewhere or to simply have wider aisles, which shoppers appreciate.

#5: Reduced Shrink & Increased Shelf Life

The Crystal Merchandiser® also helps stores by reducing product shrink and increasing shelf life, which is especially pertinent to meat departments and produce departments.

In the words of a meat department manager, “Are the products holding up better? Absolutely! There’s no question it’s enhanced the shelf-life of the products.” The manager also reported that the meat held its vibrant, fresh color longer. A meat cutter told us, “It actually preserves the meat longer, gives it more life. It’s better for the customer; they get a fresher product. It’s better for us, as a company; we save more money, and we sell more, too.”

This benefit carries over to the produce department. Anything you put in the Crystal Merchandiser® stays fresh and beautiful longer. Spoilage is down, and shoppers take home produce that is fresher. As a produce department manager told us, “Since we began using the Crystal Merchandiser®, our shrink on bagged salad and cut fruit has been reduced by as much as 50%. The consistent temperature is the key.”

Are You Ready?

Have you fallen in love with the Crystal Merchandiser® too? Now is the time to contact the Zero Zone sales team to choose the Crystal Merchandiser® for your next store.

The Genesis of Refrigeration

Genesys™ Natural Refrigeration Solutions takes us back to the beginning. Carbon dioxide (CO2) and ammonia (NH3) have always been in our environment, and they have also always been part of the story of refrigeration. Both served as refrigerants in the 1800s. However, synthetic refrigerants emerged, causing their use to decline. Now, the AIM Act and upcoming EPA rules will propel the industry away from environment-damaging HFC refrigerants and toward low global warming potential (GWP) options. Consequently, natural refrigerants are once again a rising option for refrigeration.

Introducing Genesys™ Natural Refrigeration Solutions

That is why Zero Zone presents Genesys™ Natural Refrigeration Solutions. It is time to return to the beginning—the genesis—of refrigeration with CO2 (R-744) and ammonia (R-717) systems. CO2 and ammonia are the gold standard for ozone depletion potential (ODP) and global warming potential (GWP). Neither depletes the ozone (0). CO2 has a GWP of 1, as it is used as the baseline for that scale, and ammonia has a GWP of 0. For performance, CO2 is known for its high cooling capacity, and ammonia has a reputation for excellent energy efficiency. Natural refrigerants are a future-proof solution that exceeds modern sustainability goals, allowing customers to make the best choice for themselves and for the environment. Natural refrigerants are the natural choice.

The Time to Act is Now

Upcoming EPA regulations will end the use of most HFC refrigerants by 2025. Therefore, today is the day to choose Genesys™ Natural Refrigeration Solutions for your next project. For more information about the Genesys™ CO2 systems, watch our video and learn more at our website.

The American Innovation and Manufacturing Act (AIM Act) directs the Environmental Protection Agency (EPA) to regulate the transition to alternative refrigerants. It phases down the production and consumption of HFC refrigerants. The EPA has published a proposed rule that will prohibit the manufacture of equipment containing HFCs by January 1, 2025. It will also prohibit the sale of those products by January 1, 2026.

Read more about the AIM Act in 2025 here.

Which states are affected by the AIM Act?

This rule would apply to the entire country, bringing alignment instead of state-by-state regulations. States can still issue their own, more stringent regulations. Some states, like California and New York, will still require attention.

Which refrigerants are affected?

This rule proposes to restrict the use of refrigerants by their global warming potential (GWP). Equipment using more than 200 lbs. of refrigerant will face a GWP limit of 150. Equipment using less than 200 lbs. of refrigerant will face a GWP limit of 300. Chiller systems will face a GWP limit of 700.

These GWP limits will end the use of refrigerants like R-404A (GWP of 3943), R-407A (GWP of 1923), R-410A (GWP of 1924), R-448A (GWP of 1273), R-449A (GWP of 1282), and R-507 (GWP of 3985) in new equipment. Refrigeration equipment will need to use natural refrigerants, such as CO₂ (GWP of 1) and ammonia (GWP of 0). HFO-based refrigerants will also be used since they have options below the proposed GWP limits.

When will the AIM Act ruling be finalized?

Currently, the proposed rule is available for comments until January 30, 2023. The rule will be finalized in October 2023. We do not expect the GWP limits to change. However, the implementation date might get pushed back to help manufacturers and end users complete existing projects. Industry leaders are asking for clarification about how the implementation dates are defined. They also seek clarification on how “new projects” will be defined compared to retrofit or remodel projects.

Further Reading

Zero Zone has a new paper, “The National Plan for Refrigerant Regulations,” which has more information about the upcoming EPA regulations, which states will still have regulations to follow, and solutions that Zero Zone offers.

To know where we have come from, Zero Zone has a paper, “The State of Refrigerant Regulations,” which covers state regulations that affected the United States from 2019 through 2024.

The proposed rule and a succinct fact sheet are available on the EPA website: https://www.epa.gov/climate-hfcs-reduction/technology-transitions.

If you have questions about these regulations, please contact Zero Zone and ask to speak to our Director of Regulatory Compliance & Refrigeration Technology. If you want to learn about our offerings and plan for these regulations, contact our sales team.

NASRC Factsheet on Natural Refrigerants

The North American Sustainable Refrigeration Council (NASRC) recently published a factsheet outlining the impact of natural refrigerants on supermarket refrigeration. We aim to circulate this factsheet to ensure people do not miss this valuable resource and reminder of the benefits of natural refrigerants. The NASRC advocates for natural refrigerants. In their words, “Natural refrigerants are the climate-friendly solution to mitigate supermarket HFC emissions.”

Zero Zone Natural Refrigerant Systems

Zero Zone offers natural refrigerant systems using CO₂ or ammonia. Our equipment serves both commercial and industrial settings, ranging from 5 tons to 500 tons. Additionally, our Natural Refrigerant Systems product sheet demonstrates the variety of systems we have designed and put into service. We provide CO₂ and ammonia system solutions to meet various requirements for cold storage, food processing, pharmaceutical operations, and supermarkets. Furthermore, we incorporate secondary glycol loops, air-cooled or water-cooled condensing, heat reclaim systems, and more.

CO₂ Systems

We offer CO₂ subcritical and CO₂ transcritical systems. CO₂ systems can be indoors or outdoors, set up inside custom electrical mechanical centers (CEMCs), built as full racks or condensing units, and be part of booster systems and cascade systems. This versatility unlocks CO₂ as a viable solution for warm and cool climates for all sorts of customers, and Zero Zone has been shipping these systems across the United States with great results.

Ammonia Systems

Ammonia is a great choice for industrial customers and ice arenas. Low-charge ammonia systems can be utilized indoors, outdoors, and in CEMCs. We have many years of experience and knowledge in ammonia, and we are ready for your project.

EPA Regulations and Assistance

With increasing EPA regulation limiting the continued use of HFC refrigerants, Zero Zone is eager to assist you with deciding which natural refrigerant system would be best adapted to your specific application. Begin a conversation with us. Contact your local Zero Zone sales rep today.

Do you love working with your hands? Now is the time to join our growing Zero Zone team. Current openings include both office and production positions, with leadership opportunities available.

You will be a valued member of the Zero Zone team, able to take ownership of your own career path. Gain access to professional development through internal training and tuition reimbursement. Enjoy wellness incentives, casual dress code, free coffee, and a comprehensive benefits package. Our people are known for excellent customer service, and we believe they are the best coworkers, too. We want to join you in your career goals.

We have opened a new manufacturing facility in Dyersville, Iowa, to meet the demand for quality refrigeration systems. For over 60 years, we have been a leader in refrigeration from our locations in Wisconsin, Minnesota, and now in Iowa. We have grown through dedication to our mission: “To exceed customer expectations through innovation, quality, and responsiveness.”

Zero Zone is growing. Come grow with us.

Coming Soon to the Dyersville Community!

Zero Zone brings the CHILL… We design refrigeration systems that keep fresh food cold, pharmaceuticals safe, and ice rinks frozen!

Now, you can be part of our COOL Team. Zero Zone is expanding our refrigeration systems manufacturing to Dyersville, Iowa! We need enthusiastic people for our new facility and are offering competitive wages and a collaborative environment to those who want to grow with our company! Become part of a skilled labor force where variety, cross-training, and advancement opportunities are the norm (not monotonous assembly work). Whether you’re interested in management, engineering, or manufacturing positions, now is the time to take action. Come grow with us. We have Midwestern values and a genuine do-it-right-the-first-time work ethic. If you do too, see available positions and APPLY NOW at: /careers/ or email careers.ia@zero-zone.com.

Zero Zone Systems Division, based in Ramsey, Minnesota, is a respected manufacturer of commercial and industrial refrigeration systems and chillers for retail food stores, cold storage, food processing, pharmaceutical/biomedical manufacturing, and ice arenas.

The Systems Division is part of Zero Zone Inc., headquartered in North Prairie, Wisconsin. From three facilities in Wisconsin, its Display Case Division has been manufacturing commercial coolers and freezers for supermarkets, grocery, convenience, dollar, and drug stores for over 60 years.

Zero Zone Systems Division designs and builds some of the finest refrigeration systems in North America from its main manufacturing facility in Ramsey, Minnesota and, now, from its new manufacturing location in Dyersville, Iowa.

What is the best refrigerant for my system? As government regulations push the industry away from high global warming potential (GWP) refrigerants towards low GWP options, now is the right time for natural refrigerants. Zero Zone natural refrigerant systems provide the solutions you need to meet your objectives and government regulations. A couple recent projects include a CO2 transcritical system for Rufus Brubaker Refrigeration and an ammonia chiller for Air Management Technologies.

System Facts: 200-Ton CO2 Transcritical System

- Customer: Rufus Brubaker Refrigeration

- State: Pennsylvania

- Application: Process refrigeration

- System Type: Parallel system located indoors

- Capacity: 150 tons used for medium temp, 50 tons used for low temp

- Features: Parallel compression, adiabatic gas cooler, hot gas defrost

- Energy Savings: Heat reclaim for facility water

CO2 refrigerant (R-744) grows increasingly important to the refrigeration industry as a natural replacement for high GWP refrigerants. Improvements to CO2 transcritical technology make CO2 feasible and reliable in more regions, including Pennsylvania where this new system is located. CO2 compressor discharge offers high-quality heat that can be repurposed through a heat reclaim system. Rufus Brubaker’s customer uses that reclaimed heat for their facility’s warm water.

John Collins, Industrial Sales Manager – East for Zero Zone, commented that “Rufus Brubaker is a longtime customer of Zero Zone. When they made the decision to pursue CO2 refrigeration for their customer, they came to Zero Zone as a trusted partner to deliver a successful project. Our team worked closely with Rufus Brubaker all the way through design concept, fabrication, installation, and start-up to assure a smooth project delivery and satisfied end user.”

System Facts: 150-Ton Ammonia Chiller

- Customer: Air Management Technologies

- State: Illinois

- Application: Process chilling

- System Type: Outdoor parallel system (OPS) configuration

- Capacity: 150 tons used for process cooling

- Features: Screw compressors, adiabatic condenser, low-charge plate chiller heat exchanger

- Energy Savings: VFD compressor control and DC motor condenser control

A large food processing organization globally recognized for their environmental and sustainable processes chose to install a low-charge ammonia (R-717) chiller manufactured by Zero Zone as part of a worldwide R-22 equipment phase-out. The low-charge ammonia chiller was selected to meet health and safety standards for both their employees and the surrounding neighborhood community. The package chiller was customized to provide the same low temperature glycol refrigeration capabilities of chemical refrigerant chillers while exceeding target GWP objectives. John Collins chimed in that choosing ammonia “is a future proof and environmentally friendly solution.”

Making an Educated Decision

There are many practical reasons to still consider HFCs. Traditionally, HFCs are seen as a low cost and familiar option. However, it is sometimes difficult to know where HFCs can be used because high GWP refrigerants are being increasingly regulated by individual states. To get started on understanding HFC restrictions, read our news article and white paper about state refrigerant regulations.

Likewise, there are many practical reasons for using natural refrigerants. CO2 is one of the safest refrigerants to use. Ammonia systems are some of the most efficient and have been used safely in industrial applications for many decades. Both CO2 refrigerant and ammonia refrigerant are readily available. Of course, the biggest benefit to natural refrigerants is that they are environmentally sound and meet global sustainability goals.

So, if either synthetic refrigerants or natural refrigerants can be reasonable choices, how do you know which to pick? A good place to begin is by contacting your local Zero Zone sales representative and starting a conversation. They will help you select the best refrigerant for your needs, whether it is synthetic or natural. Fill out a contact form or give us a call (cases 800-247-4496; systems 800-708-3735). We would love to talk refrigerants with you.

Bruce Hierlmeier PE, the Director of Regulatory Compliance & Refrigeration Technology for Zero Zone, was announced as a recipient of the Richard C. Schulze Award at the 2020 Air-Conditioning, Heating, & Refrigeration Institute (AHRI) Virtual Leadership Forum. The Richard C. Schulze Award is presented at the opening session to 3 individuals whose contributions influenced both AHRI and the industry as a whole. Zero Zone is incredibly proud of Bruce Hierlmeier’s contributions to the refrigeration industry.

In the presentation, Hierlmeier was recognized for his dedication to commercial refrigeration, both through AHRI and the Commercial Refrigerator Manufacturers Association (CRMA), which later merged with AHRI. Hierlmeier was credited for being instrumental to the growth of the refrigeration sector of AHRI during his service as the inaugural chair of the Refrigeration Regulatory Committee. He contributed to major revisions as chair of the Safety Standards Committee, accomplishing those revisions in less than a year to allow the safe use of flammable, low-GWP refrigerants in refrigeration systems. Hierlmeier was also regarded as an expert in regulatory compliance whose valuable input helps others understand EPA SNAP regulations and state regulations.

Additionally, Hierlmeier served as the engineering chair and later the section chair for the AHRI Commercial Refrigeration Division after the merger with CRMA. He also served as the section chair for the compressor and condensing unit section.

Bruce Hierlmeier’s contributions to the refrigeration industry extend far beyond AHRI. Hierlmeier has been a member of the American Society of Heating, Refrigerating, and Air-Conditioning Engineers (ASHRAE) since 1993 and the International Institute of Ammonia Research (IIAR) since 2016. Hierlmeier has authored and contributed to sections of the ASHRAE Handbook on Refrigeration in 2014 and 2018, a handbook that is published every 4 years and drives industry requirements. For IIAR, he served as chair of the chapters 5 & 6 subcommittees for the CO2 Handbook. He has also authored or professionally commented on sections within UL Standard 471, NSF Standard 7, DOE regulations for commercial refrigeration, and CARB regulations.

Hierlmeier’s background includes an MBA from UW-Milwaukee in 1993 and a BS in Mechanical Engineering from UW-Platteville in 1983. He has earned and maintained his professional engineer (PE) license since 1988, and he has belonged to the Order of the Engineer since 1983. He also holds a patent for an innovative air duct design that assures uniform product temperature inside Zero Zone Crystal Merchandiser™ coolers.

After being selected for the 2020 AHRI Richard C. Schulze Award, Bruce Hierlmeier was approached by his peers, who complimented his efforts and congratulated him for winning the award. Everyone at Zero Zone extends the same enthusiasm and appreciation.