Research conducted by third party, Zebrafi

Challenge #1: Extreme System Complexity & CO₂ Expertise

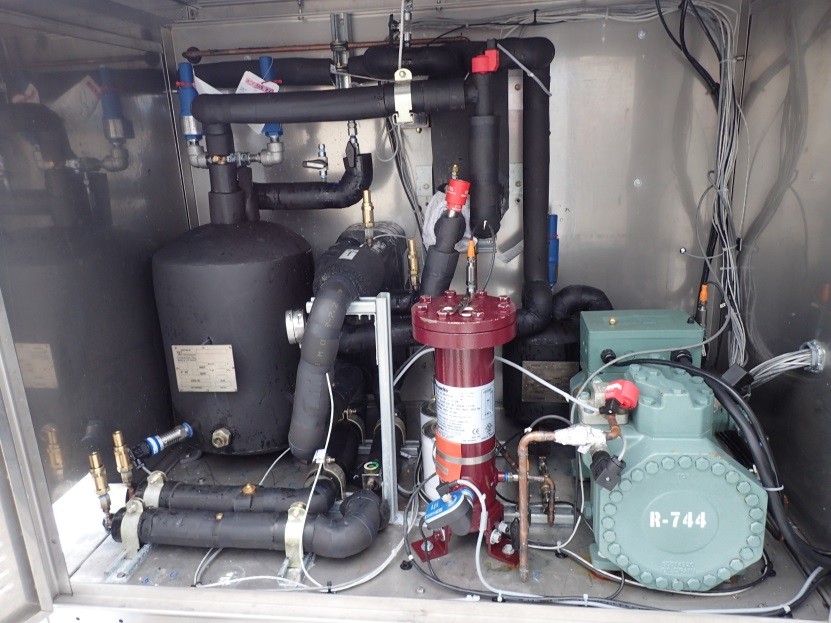

Pharmaceutical companies are rapidly transitioning away from legacy synthetic refrigerants and into natural refrigerants like CO₂. But CO₂ is not a drop in solution. Only a small number of manufacturers can operate safely and efficiently in this window, especially at -40°F.

Solution

The Zero Zone engineering team designs CO₂ systems

specifically for these extreme conditions. Estes complements this expertise with on-site execution

experience dating back more than a decade. Together they

deliver systems that maintain temperature stability, avoid dry ice formation, reduce failure risk, and maintain the strict control required in GMP environments.

“CO2 is relatively new… and you’re going to want the experience that Zero Zone is going to bring to the table.”

“In California there’s only one refrigerant for -40 right now, and it’s CO₂.”

“A2L’s are for those that can’t do CO₂ well. We’ve recently done four -40 CO₂ freezers with Zero Zone.”

-Mark Doninelli, Vice President, Estes Refrigeration

Challenge #2: Need for Trusted Engineering Support

In pharmaceutical applications, access to qualified engineers is as important as the equipment itself. Regulatory constraints, production demands, and qualification requirements leave no margin for slow support, unavailable experts, or trial and error troubleshooting.

Solution: Direct Support by Zero Zone Engineering

One of the Zero Zone defining advantages is its willingness to make senior engineers accessible for complex projects. Rather than routing support through generic channels, Zero Zone maintains active relationships between Estes and engineers who understand the systems intimately.

“I’m always able to get a hold of my Zero Zone engineering contacts and work through it.”

This eliminates delays, accelerates troubleshooting, and helps Estes keep highly regulated installations stable and compliant.

“For our customer base, saving a couple dollars up front generally isn’t their objective. What I would say is if you use Zero Zone, you will have the support.

-Mark Doninelli, Vice President, Estes Refrigeration

Challenge #3: Proven Pharmaceutical Track Record

Pharma companies do not gamble on refrigeration. They require documented proof that a partner can consistently meet temperature requirements, qualification standards, startup demands, and facility integration needs. They must also comply with regulations by entities like the FDA and ensure traceability.

Solution: Documented Success Across All Critical Temperature Classes Supported by a Culture of Trust

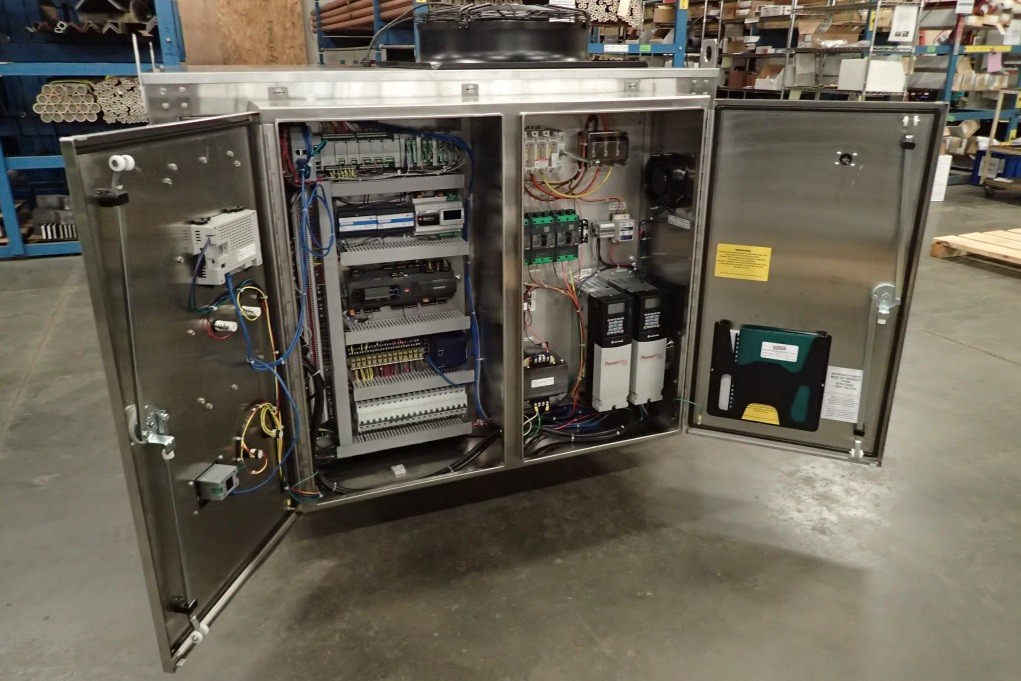

Zero Zone and Estes have delivered successful rooms across a range of environments, including some of the most technically demanding rooms at a top five pharma company. Zero Zone systems use microprocessor and PLC controls compatible with SCADA systems

(Supervisory Control and Data Acquisition). SCADA systems monitor, automate, visualize and log data for real time corrective action.

“That project we just finished for a top five pharma company… it’s about as sophisticated as it gets in our industry.”

The record speaks for itself. Estes highlights that Zero Zone is not simply a vendor but a proven partner that has delivered repeatedly in the conditions that matter most.

“Our win rate is 60-75% of the projects we quote with Zero Zone. If someone looks at anyone else, I feel like we are not doing our job up-front.”

Challenge #4: Long-Term Reliability & Continuous Improvement

Estes expects and participates in refinement and technical improvement.

Solution: A Partnership Focused on Long Term Performance, Ongoing Learning, and Never Quitting

Estes values Zero Zone because both organizations share a commitment to system longevity and continuous improvement. The two teams integrate lessons learned into subsequent installations, improving design standards, component selection, and commissioning each time.

“We continue to work to get better, make every project better than the prior.”

“When things don’t work, we’re in the battle to stick around until it does work.”

-Mark Doninelli, Vice President, Estes Refrigeration

Summary of Metrics and Outcomes

Project Experience & Delivery

- 10+ year partnership

- Four CO₂ -40°F freezers successfully delivered

- Temperature range competency: -40°F to 40°F

- Successful execution at the edge of physical limits:

“You’re right on the edge of dry ice in your refrigerant lines.

Business Performance Indicators

- Customer estimates 60–75% win rate across all projects.

- 80–90%+ win rate in large enterprise pharma accounts.

Longevity & Total Cost Perspective

- Customer-recommended lifecycle expectation:

“Done with that unit for the next 25 years.”

Support & Operational Excellence

- Direct engineering access resulting in fast resolution and high customer satisfaction.

- Trust in Zero Zone to solve the industry’s most complex refrigeration problems.