Refrigeration Load Requirements & Challenges

Private label juice manufacturer Citrus Systems, Inc. specializes in pasteurizing an extensive line of juices and fruit drinks. The business provides juice to local dairies, grocery stores, and institutional customers. Their success and future contracts led them to build a new facility that is twice as large as their previous location. Consequently, this expansion presented several challenges for their refrigeration needs.

Large Capacity Needed

To accommodate their increased production, Citrus Systems required:

- 2 pasteurizers

- 6 packaging lines

- 18 blending and storage vessels

- Over 560,000 cubic feet of storage

- Doubled square footage from the previous facility

- A system that follows precise HACCP food safety guidelines from the FDA

The Zero Zone Refrigeration Solution

To meet these demands, Zero Zone provided three refrigeration systems:

- A low temperature rack offering 82 tons of cooling at -23°F

- A medium temperature rack providing 124 tons of cooling at +20°F

- A 4-circuit chiller delivering 240 tons of cooling at +18°F

Additionally, Zero Zone designed and built a package rack system to be installed on-site. To ensure food safety, the system includes remote monitoring and diagnostics.

The refrigeration systems are designed to provide trouble-free, energy-efficient operation for Citrus Systems’ production process. Zero Zone incorporated features and technology tailored to the needs of pasteurization plants, such as multiple chilling circuits, industrial PLC controls, and evaporative condensing with variable speed fan control. Furthermore, a heat reclaim system off the compressor discharge circuit reduces both electric and natural gas demand by repurposing heat for hot water used throughout the production facility.

Guaranteeing that the system always maintains the correct temperature is essential for Citrus Systems’ HACCP program. To monitor operations and communicate any alarm conditions, Citrus Systems implemented a remote diagnostics system connected to the refrigeration equipment. Consistency and dependability are crucial in the pasteurization and food processing industries to protect the quality of the final product.

A Satisfied Customer

Thomas E. Boehland, founder and president of Citrus Systems, takes great satisfaction in how everything came together, describing the equipment as “a work of art.” He praised the Zero Zone team: “You can tell that there is a lot of pride in what they put together. It isn’t just a bunch of refrigeration components cobbled together on-site to get the job done. It’s a nice package, and you can tell just by looking at it. The factory people take pride in it and even sign off on the equipment with each individual person putting their names to it. You don’t see that very often these days.” Boehland concluded by saying, “I’ve put my faith in Zero Zone to do what we need to be done.”

Contact our sales team to start on your next refrigeration journey.

Read more in the full case study: “An Industrial Work of Art.”

The Genesis of Refrigeration

Genesys™ Natural Refrigeration Solutions takes us back to the beginning. Carbon dioxide (CO2) and ammonia (NH3) have always been in our environment, and they have also always been part of the story of refrigeration. Both served as refrigerants in the 1800s. However, synthetic refrigerants emerged, causing their use to decline. Now, the AIM Act and upcoming EPA rules will propel the industry away from environment-damaging HFC refrigerants and toward low global warming potential (GWP) options. Consequently, natural refrigerants are once again a rising option for refrigeration.

Introducing Genesys™ Natural Refrigeration Solutions

That is why Zero Zone presents Genesys™ Natural Refrigeration Solutions. It is time to return to the beginning—the genesis—of refrigeration with CO2 (R-744) and ammonia (R-717) systems. CO2 and ammonia are the gold standard for ozone depletion potential (ODP) and global warming potential (GWP). Neither depletes the ozone (0). CO2 has a GWP of 1, as it is used as the baseline for that scale, and ammonia has a GWP of 0. For performance, CO2 is known for its high cooling capacity, and ammonia has a reputation for excellent energy efficiency. Natural refrigerants are a future-proof solution that exceeds modern sustainability goals, allowing customers to make the best choice for themselves and for the environment. Natural refrigerants are the natural choice.

The Time to Act is Now

Upcoming EPA regulations will end the use of most HFC refrigerants by 2025. Therefore, today is the day to choose Genesys™ Natural Refrigeration Solutions for your next project. For more information about the Genesys™ CO2 systems, watch our video and learn more at our website.

The American Innovation and Manufacturing Act (AIM Act) directs the Environmental Protection Agency (EPA) to regulate the transition to alternative refrigerants. It phases down the production and consumption of HFC refrigerants. The EPA has published a proposed rule that will prohibit the manufacture of equipment containing HFCs by January 1, 2025. It will also prohibit the sale of those products by January 1, 2026.

Read more about the AIM Act in 2025 here.

Which states are affected by the AIM Act?

This rule would apply to the entire country, bringing alignment instead of state-by-state regulations. States can still issue their own, more stringent regulations. Some states, like California and New York, will still require attention.

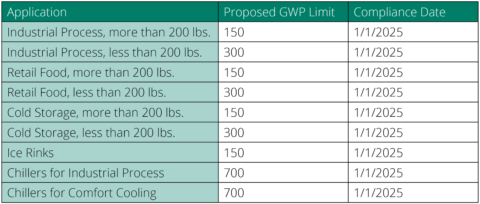

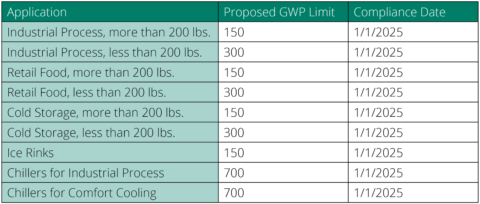

Which refrigerants are affected?

This rule proposes to restrict the use of refrigerants by their global warming potential (GWP). Equipment using more than 200 lbs. of refrigerant will face a GWP limit of 150. Equipment using less than 200 lbs. of refrigerant will face a GWP limit of 300. Chiller systems will face a GWP limit of 700.

These GWP limits will end the use of refrigerants like R-404A (GWP of 3943), R-407A (GWP of 1923), R-410A (GWP of 1924), R-448A (GWP of 1273), R-449A (GWP of 1282), and R-507 (GWP of 3985) in new equipment. Refrigeration equipment will need to use natural refrigerants, such as CO₂ (GWP of 1) and ammonia (GWP of 0). HFO-based refrigerants will also be used since they have options below the proposed GWP limits.

When will the AIM Act ruling be finalized?

Currently, the proposed rule is available for comments until January 30, 2023. The rule will be finalized in October 2023. We do not expect the GWP limits to change. However, the implementation date might get pushed back to help manufacturers and end users complete existing projects. Industry leaders are asking for clarification about how the implementation dates are defined. They also seek clarification on how “new projects” will be defined compared to retrofit or remodel projects.

Further Reading

Zero Zone has a new paper, “The National Plan for Refrigerant Regulations,” which has more information about the upcoming EPA regulations, which states will still have regulations to follow, and solutions that Zero Zone offers.

To know where we have come from, Zero Zone has a paper, “The State of Refrigerant Regulations,” which covers state regulations that affected the United States from 2019 through 2024.

The proposed rule and a succinct fact sheet are available on the EPA website: https://www.epa.gov/climate-hfcs-reduction/technology-transitions.

If you have questions about these regulations, please contact Zero Zone and ask to speak to our Director of Regulatory Compliance & Refrigeration Technology. If you want to learn about our offerings and plan for these regulations, contact our sales team.

NASRC Factsheet on Natural Refrigerants

The North American Sustainable Refrigeration Council (NASRC) recently published a factsheet outlining the impact of natural refrigerants on supermarket refrigeration. We aim to circulate this factsheet to ensure people do not miss this valuable resource and reminder of the benefits of natural refrigerants. The NASRC advocates for natural refrigerants. In their words, “Natural refrigerants are the climate-friendly solution to mitigate supermarket HFC emissions.”

Zero Zone Natural Refrigerant Systems

Zero Zone offers natural refrigerant systems using CO₂ or ammonia. Our equipment serves both commercial and industrial settings, ranging from 5 tons to 500 tons. Additionally, our Natural Refrigerant Systems product sheet demonstrates the variety of systems we have designed and put into service. We provide CO₂ and ammonia system solutions to meet various requirements for cold storage, food processing, pharmaceutical operations, and supermarkets. Furthermore, we incorporate secondary glycol loops, air-cooled or water-cooled condensing, heat reclaim systems, and more.

CO₂ Systems

We offer CO₂ subcritical and CO₂ transcritical systems. CO₂ systems can be indoors or outdoors, set up inside custom electrical mechanical centers (CEMCs), built as full racks or condensing units, and be part of booster systems and cascade systems. This versatility unlocks CO₂ as a viable solution for warm and cool climates for all sorts of customers, and Zero Zone has been shipping these systems across the United States with great results.

Ammonia Systems

Ammonia is a great choice for industrial customers and ice arenas. Low-charge ammonia systems can be utilized indoors, outdoors, and in CEMCs. We have many years of experience and knowledge in ammonia, and we are ready for your project.

EPA Regulations and Assistance

With increasing EPA regulation limiting the continued use of HFC refrigerants, Zero Zone is eager to assist you with deciding which natural refrigerant system would be best adapted to your specific application. Begin a conversation with us. Contact your local Zero Zone sales rep today.

What is the best refrigerant for my system? As government regulations push the industry away from high global warming potential (GWP) refrigerants towards low GWP options, now is the right time for natural refrigerants. Zero Zone natural refrigerant systems provide the solutions you need to meet your objectives and government regulations. A couple recent projects include a CO2 transcritical system for Rufus Brubaker Refrigeration and an ammonia chiller for Air Management Technologies.

System Facts: 200-Ton CO2 Transcritical System

- Customer: Rufus Brubaker Refrigeration

- State: Pennsylvania

- Application: Process refrigeration

- System Type: Parallel system located indoors

- Capacity: 150 tons used for medium temp, 50 tons used for low temp

- Features: Parallel compression, adiabatic gas cooler, hot gas defrost

- Energy Savings: Heat reclaim for facility water

CO2 refrigerant (R-744) grows increasingly important to the refrigeration industry as a natural replacement for high GWP refrigerants. Improvements to CO2 transcritical technology make CO2 feasible and reliable in more regions, including Pennsylvania where this new system is located. CO2 compressor discharge offers high-quality heat that can be repurposed through a heat reclaim system. Rufus Brubaker’s customer uses that reclaimed heat for their facility’s warm water.

John Collins, Industrial Sales Manager – East for Zero Zone, commented that “Rufus Brubaker is a longtime customer of Zero Zone. When they made the decision to pursue CO2 refrigeration for their customer, they came to Zero Zone as a trusted partner to deliver a successful project. Our team worked closely with Rufus Brubaker all the way through design concept, fabrication, installation, and start-up to assure a smooth project delivery and satisfied end user.”

System Facts: 150-Ton Ammonia Chiller

- Customer: Air Management Technologies

- State: Illinois

- Application: Process chilling

- System Type: Outdoor parallel system (OPS) configuration

- Capacity: 150 tons used for process cooling

- Features: Screw compressors, adiabatic condenser, low-charge plate chiller heat exchanger

- Energy Savings: VFD compressor control and DC motor condenser control

A large food processing organization globally recognized for their environmental and sustainable processes chose to install a low-charge ammonia (R-717) chiller manufactured by Zero Zone as part of a worldwide R-22 equipment phase-out. The low-charge ammonia chiller was selected to meet health and safety standards for both their employees and the surrounding neighborhood community. The package chiller was customized to provide the same low temperature glycol refrigeration capabilities of chemical refrigerant chillers while exceeding target GWP objectives. John Collins chimed in that choosing ammonia “is a future proof and environmentally friendly solution.”

Making an Educated Decision

There are many practical reasons to still consider HFCs. Traditionally, HFCs are seen as a low cost and familiar option. However, it is sometimes difficult to know where HFCs can be used because high GWP refrigerants are being increasingly regulated by individual states. To get started on understanding HFC restrictions, read our news article and white paper about state refrigerant regulations.

Likewise, there are many practical reasons for using natural refrigerants. CO2 is one of the safest refrigerants to use. Ammonia systems are some of the most efficient and have been used safely in industrial applications for many decades. Both CO2 refrigerant and ammonia refrigerant are readily available. Of course, the biggest benefit to natural refrigerants is that they are environmentally sound and meet global sustainability goals.

So, if either synthetic refrigerants or natural refrigerants can be reasonable choices, how do you know which to pick? A good place to begin is by contacting your local Zero Zone sales representative and starting a conversation. They will help you select the best refrigerant for your needs, whether it is synthetic or natural. Fill out a contact form or give us a call (cases 800-247-4496; systems 800-708-3735). We would love to talk refrigerants with you.

Not even refrigeration regulations are simple after 2020. Refrigerant regulations are changing, and getting new refrigeration equipment is complicated. This adds more challenges to stores, cold storage warehouses, pharmaceutical plants, and more.

Here is the brief summary of recent refrigerant regulations. The United States Environmental Protection Agency (EPA) issued SNAP Rules 20 and 21 in 2015 and 2016 to eliminate the use of refrigerants with high global warming potential (GWP), but those rules were vacated by the D.C. circuit court in 2017 and 2019. Since then, individual states have taken responsibility for issuing their own regulations. So far, most state regulations target the same high GWP refrigerants, but they have different effective dates and even define the effective dates differently. This creates a challenge for both buyers and manufacturers who need to know whether their new equipment will be compliant.

Zero Zone wants to help by providing the effective dates and a map so it is clear whether your state has any regulations. Check out our article about The State of Refrigerant Regulations. Please note that we recommend that our customers contact their state’s environmental regulatory department to clarify the nuances, but our research will be a valuable starting point.

Let’s talk about hockey. Or do you prefer figure skating? Maybe you’re a little nerdy (like us!) and want to talk about CO2 transcritical refrigeration. You are in luck, because the St. Michael-Albertville (STMA) Ice Arena has all of that!

The STMA story is about an ice arena that had too many skaters and not enough ice time to go around. The STMA School District replaced their existing system with a Zero Zone ColdLoop™ Ice Arena Chiller that cools both their original ice sheet and a new ice sheet. Terry Zerwas, the school’s Director of Buildings & Grounds, described the transition as “flawless,” and their Activities Director Keith Cornell spoke about how this gives the boys’ and girls’ hockey teams a real home. Their rink is ready for hockey players and figure skaters alike. “An Olympic skater had a program here,” explained Terry Zerwas, “and that Olympic skater found that it was the best that they had skated on.”

St. Cloud Refrigeration (SCR) was responsible for installing the ColdLoop™ Chiller. SCR Owner Mark Fitch says their relationship with Zero Zone goes back 40 years. “We’ve always been very familiar with Zero Zone’s equipment. They put together a very nice product for us.”

The design team chose CO2 as the primary refrigerant that works with a secondary glycol loop. Arena Manager Grant Fitch believes CO2 could be “the future” for ice rinks, and Mark Fitch is confident that “CO2 will be around and will not be phased out and will actually get bigger and bigger as time goes on.” CO2 is a very efficient and safe refrigerant. People question CO2 because it operates at very high pressures, but Mark Fitch says that is not a big concern. “Every component is built to deal with this pressure,” he states, comparing the system to other high pressure applications in homes and apartments. If high pressure is there, the system will be built to accommodate it.

This is just the tip of the iceberg. Want to know more? You don’t even need to travel to Minnesota. Watch our video or read our full case study about the STMA Ice Arena to see it for yourself. Learn about our full capabilities in our new ColdLoop™ Ice Arena Chillers Brochure.

The Crown Coliseum in Cumberland County, NC, is home to the Fayetteville Marksmen minor league hockey team. It also became the home to a brand new Zero Zone ColdLoop™ Ice Arena Chiller.

After years with an old R-22 system, Cumberland County turned to Zero Zone for a new chiller using ammonia. Ammonia is an industrial-grade refrigerant. “Ammonia as a refrigerant is an excellent choice,” Industrial Sales Manager John Collins explained. “It is perfectly suited for a low-temperature chiller application: highly efficient and very reliable.” Ammonia is a future-proof refrigerant with no ozone depletion potential (ODP = 0), no global warming potential (GWP = 0), and high performance. It is one of the most prominent natural refrigerants, which is appealing as an environmentally responsible option.

Cumberland County also chose many excellent cost-saving features: highly efficient screw compressors, evaporative condenser, PLC control system, variable frequency drives (VFDs), and, most notably, a heat reclaim system. Their heat reclaim system repurposes compressor discharge heat to warm the subfloor under the ice, ensuring that the subfloor will not freeze or crack. Heat reclaim systems repurpose the waste heat that otherwise would be released at the condenser without benefitting the arena.

Most importantly, the chiller produces high-quality ice for the hockey team. The Fayetteville Marksmen skate confidently because their home ice is formed by a ColdLoop™ Chiller.

Download our Crown Coliseum case study to learn more!

We take our home refrigerators for granted. We put food into the refrigerator, and it makes the food cold. But actually, the refrigerator is not making the food cold; it is removing heat from the food. That might sound counterintuitive, so we invite you to open the door to the world of refrigeration by learning about the basics of the refrigeration cycle.

Heat Transfer & Pressure

Before we discuss the refrigeration cycle, we must briefly discuss heat transfer. Heat always transfers from warm to cold. You can see evidence of this in your beverage of choice. Your morning coffee may start hot, but as the day wears on, it gets cooler because heat transfers into the surrounding air. At lunch, your soda warms up as heat transfers from the surrounding air. This is called sensible heat transfer. You can remember this by thinking about how you can sense (feel) the change. The coffee mug feels hot as heat transfers to you; the soda can feels cold as heat transfers from you.

Heat transfer can also cause a substance to change state between solid, liquid, and gas. This is called latent heat transfer. For example, H2O can exist as a solid (ice), a liquid (water), or a gas (steam). At sea level, H2O will be water between 212°F (100°C) and 32°F (0°C). If water is heated beyond 212°F, it will evaporate into steam. If water is cooled below 32°F, it will freeze into ice. As a substance changes state, its original state will be reduced as the other state increases. For example, as ice melts, it disappears and the amount of water increases. If enough heat transfers, the substance will cease to exist in its original state. Latent heat transfer (changing state) takes more heat than sensible heat transfer (changing temperature).

Another factor is how pressure relates to temperature. Boiling points vary depending on the pressure surrounding the substance. At sea level, water boils at 212°F, but if you travel to Denver or Pikes Peak in Colorado, the atmospheric pressure is lower and the boiling point will be lower.

The Refrigeration Cycle

Your unfinished can of soda is now warm. How do you chill it again? You may think the answer is to add cold to it, but remember that heat only moves from warm to cold. It is more accurate to say that you are actually removing the heat from the soda by transferring that heat to another, colder object. This is the concept behind the refrigeration cycle.

The refrigeration cycle comes from the work of William John Macquorn Rankine, who discovered how to transfer heat away from objects that were already cool. Historically, this could be done by placing objects into an ice box. Ice works well as a refrigerant because it maintains a constant 32°F temperature. Warm product (milk, meat, etc.) transfers heat to the ice (latent heat transfer), causing the ice to melt into water. The water (full of heat) drains away, and the refrigerated space and product remain cool.

All modern refrigeration systems have four main components that work together to move heat: the evaporator, the compressor, the condenser, and the expansion device. Imagine that heat moves in a “bucket” and follow the bullet points which correspond to the figure.

- The evaporator gathers/absorbs heat from the refrigerated space into a “bucket.” The “bucket” is low-pressure, and it changes state (latent heat transfer) as it absorbs heat. Then the evaporator moves the low-pressure, heat-filled “bucket” to the compressor.

- The compressor applies pressure, which compresses the heat-filled “bucket.” The heat-filled “bucket” changes from low-pressure to high-pressure as the compressor pushes it from the colder evaporator to the warmer condenser. When pressure is added, the temperature of the “bucket” also increases.

- The condenser takes the high-pressure, heat-filled “bucket” and releases the heat from the “bucket” to the outside air (or other application). The “bucket” changes state (latent heat transfer) again as it releases heat.

- The expansion device relieves the pressure on the empty “bucket.” When pressure is reduced, the temperature also decreases. The “bucket” cools and expands on its way to the evaporator to absorb more heat again.

The downside of using ice as the “bucket” is that more ice must constantly be added as it melts away. Modern refrigeration systems needed a long-term solution. Refrigerants are the modern “bucket” because refrigerants can continually absorb and release energy without escaping the system. Refrigerants change state between a liquid to a gas. Refrigerants must be able to boil at low pressures and low temperatures to be efficient.

High-glide refrigerants have a unique effect on a refrigeration system.

Have questions? Contact us and ask for our Director of Regulatory Compliance & Refrigeration Technology.

The California Air Resources Board (CARB) has officially published details about the California Cooling Act, which will take effect on January 1, 2019. The Act, which is based on vacated EPA SNAP Rule 20, prohibits HFC refrigerants with high global warming potential (GWP)—such as R-404A and R-507A—for supermarket systems, condensing units, and self-contained units.

The California Cooling Act affects new and retrofit equipment. Manufacturers cannot sell equipment using prohibited refrigerants that are manufactured after January 1, 2019.

CARB Definition for New Refrigeration Equipment:

- Any refrigeration equipment that is first installed using new or used components; or

- Any refrigeration equipment that is modified such that it is:

- Expanded after the date at which this subarticle becomes effective, to handle an expanded cooling load by the addition of components in which the capacity of the system is increased, including refrigerant lines, evaporators, compressors, condensers, and other components; or

- Replaced or cumulatively replaced after the date at which this subarticle becomes effective, such that the capital cost of replacing or cumulatively replacing components exceeds 50 percent of the capital cost of replacing the entire refrigeration system.

If the retailer or engineer is unsure whether the work will classify as a new system, they should contact the Refrigerant Management Program Hotline at 916-324-2517 or rmp@arb.ca.gov.

Additional Reading:

Refer to the following for more information about California’s regulations or the EPA regulations that affect the rest of the country:

For further information, contact Zero Zone at 800-247-4496 and ask for our Department of Regulatory Compliance and Refrigeration Technology. This message is informational only, and customers should review the new regulations fully to ensure compliance.