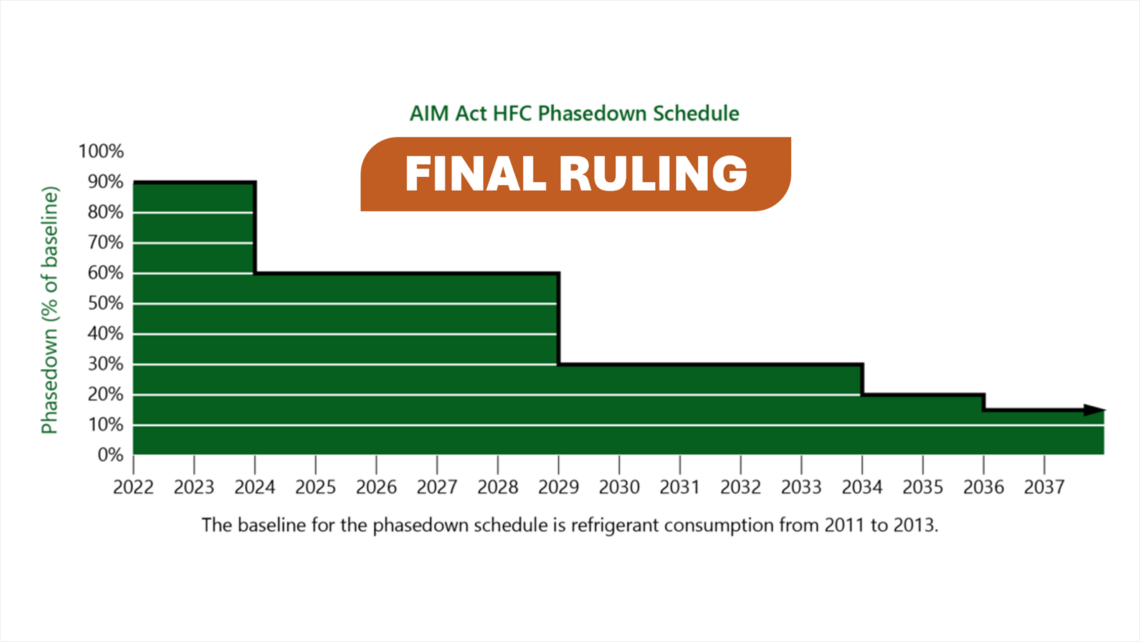

The American Innovation and Manufacturing Act (AIM Act) was passed in 2020 by bipartisan support in the U.S Congress as the United States joined the global movement to reduce human impact on climate change. The AIM Act directs the U.S. Environmental Protection Agency (EPA) to oversee the phasedown of HFC refrigerant production and consumption in an effort to transition to alternative refrigerants. The AIM Act includes a phasedown schedule that began in 2022 and continues to 2036.

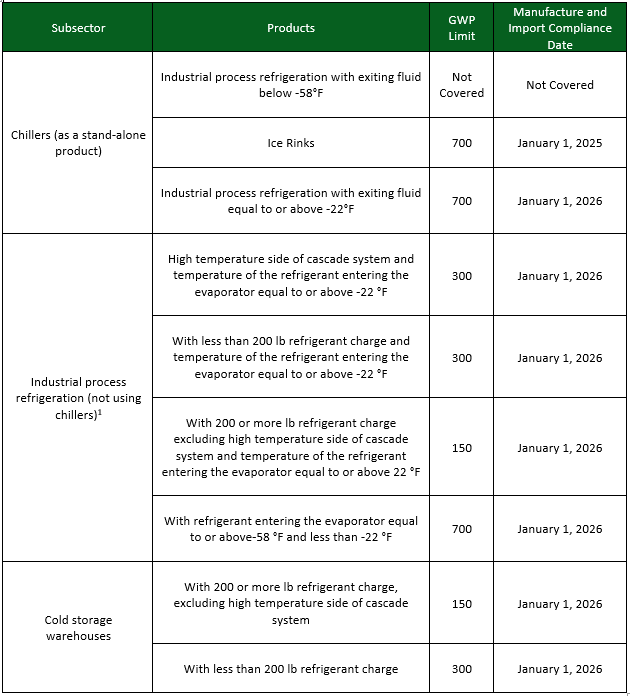

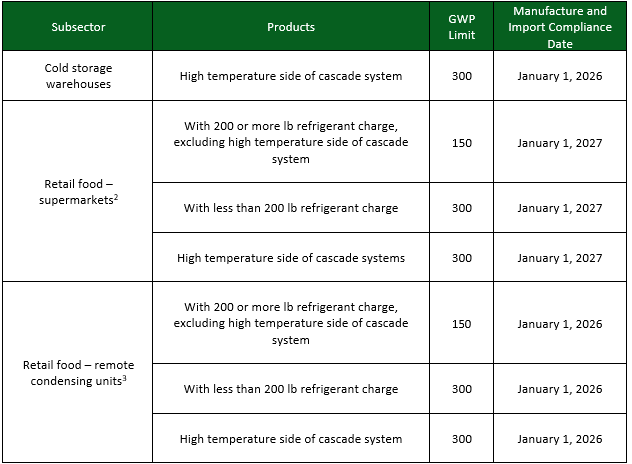

The new rule prohibits the manufacture and import of self-contained products that use hydrofluorocarbons (HFCs). The rule also prohibits the sale, distribution, and export of products three years after the manufacture and import restriction. Finally, it prohibits the installation of new refrigeration air conditioning and heat pump (RACHP) systems that contain HFCs. The compliance dates of these new rules vary based on sector and subsector.

Who does the AIM Act refer to?

The final rule states, “Entities that manufacture, import, export, sell, distribute, or install systems or products that use HFCs in refrigerants and air-conditioning equipment systems, heat pumps, foams, and aerosols may be affected by this new rule. Restrictions apply to original equipment manufacturers, product distributors, retailers, and companies that direct the installation of new RACHP systems.”

Important definitions

The final rule makes a distinction between products and systems. Certain products and the installation of certain systems have different restrictions.

A product is functional upon leaving a factory. Examples of products include self-contained refrigerators and self-contained ice machines. The EPA is restricting the sale, distribution and export of products containing higher-GWP HFCs three years after the manufacture and import restriction dates.

A system is assembled and charged in the field using multiple components. An example of a system is a supermarket refrigeration system that include a centralized compressor room. Components include equipment such as compressors, condensers, and display cabinets. There is not a restriction on the manufacture, import, sale, distribution, or export of components that are used to repair existing systems.

When will the phasedown start?

Self-Contained Configuration

Remote Configuration

- Industrial Process Refrigeration (IPR) systems are used to cool process streams at a specific location in manufacturing and other industrial processes (e.g., chemical, pharmaceutical, petrochemical, and manufacturing industries).

- Refers to the Zero Zone Hybrid™ display cases and rack condensing units (Edge XT).

- Refers to Zero Zone’s Highlight®, Crystal®, and Reveal® display cases and their associated systems.

Why was the AIM Act proposed and passed?

The AIM Act addresses petitions from industry, environmental organizations, and state governments to restrict the use of HFCs. The EPA has estimated the potential benefits of this rule will provide savings to American consumers and industry through energy efficiency and lower-cost refrigerants. The EPA stated that this rule will also result in greenhouse gas emissions reduction benefits.

- EPA estimations:

- Emission reduction of 876 million metric tons of carbon dioxide equivalent through 2050.

- $50.4 billion in climate change mitigation benefits

- $4.5 billion in cost savings to consumers and businesses driven by the lower cost of HFC substitutes and increased energy efficiency of lower-GWP refrigerants

For our customers

This rule does not restrict Zero Zone customers from using their existing refrigeration systems. The EPA has allowed an existing system to continue its operation to the end of its useful life. The systems may be serviced and repaired throughout their use, including replacing components. Components needed for repair are allowed to continue being manufactured.

For new installations, the equipment needs to be charged before the compliance dates. The following actions are considered a new installation:

- Assembling a system for the first time from used or new components;

- Increasing the cooling capacity, in BTU per hour, of an existing system; or

- Replacing 75 percent or more of evaporators (by number) and 100 percent of the compressor racks, condensers, and connected evaporator loads of an existing system.

Into the Future: Refrigerant Management

Although a system can be serviced until the end of its useful life, the refrigerants used to recharge it will become scarce as production slows. The costs of synthetic refrigerants are expected to rise. The EPA is currently working on a standard for refrigerant reclamation and requirements for reclaimed HFC refrigerants. They are proposing that as of January 1, 2028, reclaimed refrigerant must be used when servicing and/or repairing refrigerant-containing equipment. This includes supermarket systems and stand-alone retail food refrigeration.

If you have questions about these regulations, please contact Zero Zone and ask to speak to our Director of Regulatory Compliance & Refrigeration Technology, Bruce Hierlmeier.

How can Zero Zone Help?

At Zero Zone, we’ve always been green. Zero Zone offers sustainable refrigeration solutions with Genesys™ Natural Refrigeration Solutions. If you want to learn about our offerings and plans for these new regulations, contact our sales team or visit Zero Zone’s Genesys™ Natural Refrigeration Solutions webpage.

View the infographics for our Retail and Industrial customers for a summary of important facts and dates.