The Refrigerants of 2026

The refrigeration industry is approaching a major transition. Under the American Innovation and Manufacturing (AIM) Act, the United States is phasing down the use of high-GWP refrigerants—most notably traditional HFCs. Starting January 1, 2026, these refrigerants will no longer be permitted in new commercial or industrial refrigeration systems. However, systems installed before this deadline can continue operating and be serviced throughout their useful life, provided repairs don’t result in a full system replacement.

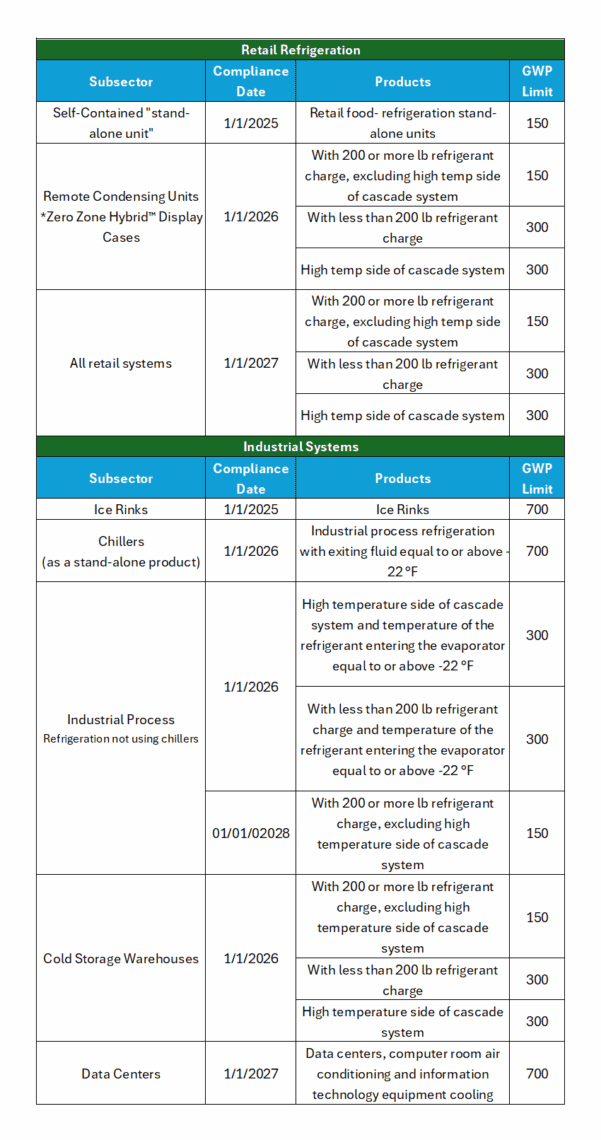

The AIM Act, passed in 2020, directs the EPA to cut HFC production and consumption by 85% by 2036. This phasedown began in 2022 and is reinforced by the Technology Transition Rule, finalized in October 2023. This rule sets the maximum GWP limits for refrigerants in new systems. Each sector in the refrigeration industry has varying compliance dates. Understanding these compliance dates will help you make the right choice for the future.

Changes Starting January 1, 2026

Retail & Commercial Refrigeration

- Remote condensing units with a refrigerant charge greater than or equal to 200 lbs.

- GWP limit of 150

- Remote condensing units less than 200 lbs.

- GWP limit of 300

- High-temp side of cascade systems

- GWP limit of 300 lbs.

Self-contained refrigeration stand-alone units were limited to a GWP of 150 in 2025. All retail systems will be limited to a GWP of 300 in 2027.1

Industrial Applications

- Industrial process refrigeration with exiting fluid equal to or above -22°F (Chillers)

- GWP limit of 7001

- Industrial process refrigeration not using chillers

- GWP limit of 3001

- Cold storage warehouses

- GWP limit of 3001

Notes:

- For more information, view our retail and industrial infographics.

Refrigerants Being Phased Out

- R-404A (GWP 3,920)

- R-448A (GWP 1,360)

- R-134A (GWP 1,430)

Planning Ahead

The AIM Act represents more than just a regulatory shift—it’s a strategic opportunity to invest in refrigeration systems that deliver both performance and sustainability. Natural refrigerants like propane, CO₂, and ammonia offer high efficiency and long-term reliability, making them ideal choices for businesses preparing for the future of cooling. To balance the function of traditional refrigerants with sustainability and efficiency, A2L options are also available.

The Refrigerants of the Future

R-744 (CO₂)

R-290 (Propane)

R-454C (A2L)

R-717 (Ammonia)

Choosing the Right Refrigerant

All refrigerants have their advantages and disadvantages. As businesses prepare for AIM Act compliance, here are key considerations for the refrigerants of 2026:

- CO2

- Operates at higher pressures than traditional refrigerants

- Requires specialized components for safe and efficient use

- Propane

- Highly flammable and requires strict handling protocols

- Charge limits restrict its use in larger systems

- A2L Refrigerants

- Mildly flammable; require leak detection and ventilation systems

- Use may be restricted by local building and safety codes

- Ammonia

- Toxic and requires careful handling and safety measures

- Corrosive to certain metals, necessitating compatible materials in system design

While each refrigerant presents unique challenges, understanding these considerations is key to selecting the right solution for your application. Whether you’re designing a new system or retrofitting an existing one, working with experienced partners and planning for safety, compliance, and long-term performance will ensure your refrigeration strategy is ready for 2026 and beyond.

Next Generation Refrigeration

As the refrigeration industry moves toward a low-GWP future, understanding your options and planning ahead will be key to staying compliant and competitive. Whether you’re upgrading a single display case or designing a full-scale industrial system, choosing the right refrigerant and system design today will position your business for long-term success.

Zero Zone is committed to helping you navigate the refrigerant transition with confidence. To explore your options and stay informed on the latest industry updates, visit our Refrigeration Hub.

Learn more about our natural refrigeration options on the Genesys™ products page and discover how A2L refrigerants can fit into your application by visiting our A2L refrigerants page.

To view a listing of all Zero Zone offerings, visit our products page. If you still have questions, or want help with designing your future solution, contact one of our sales reps today.