Refrigeration engineers and service contractors need to understand the difference between bubble point (when a substance starts boiling) and dew point (when a substance finishes boiling) because high-glide refrigerants do not boil at a constant temperature. If refrigeration professionals do not know these terms or use them incorrectly, equipment will be inefficient and possibly be damaged. Let’s glide into this discussion about high-glide refrigerants.

Refrigerant Glide

Water boils at a consistent temperature. When you set a pot of water to boil, the water will boil at the same temperature whether the pot holds 1 cup of water or 2 cups of water. Even as the water evaporates, the remaining water boils at the same temperature. This is because the only substance being boiled is water.

Many refrigerants also have a consistent boiling point, whether they are natural refrigerants or synthetic refrigerants. But high-glide refrigerants do not boil at a consistent temperature. A high-glide refrigerant may start boiling at 18°F, but as it boils into a gas, the boiling point “glides” up to 28°F. Why does this happen? High-glide refrigerants are a blend of different refrigerants, and these refrigerants separate when they are brought to boiling. Since each refrigerant boils at different temperatures, they will evaporate into a gas at different points, which changes the composition and concentration of the remaining liquid refrigerant. This causes the boiling point to “glide.”

Let’s consider a high-glide refrigerant that is composed equally of three different refrigerants, and each boil at different temperatures; for example, 18°F, 23°F, and 28°F.

- Below 18°F, the composition is completely liquid and not boiling.

- At 18°F, the first refrigerant boils away. This changes the composition and concentration of the refrigerant blend, and the remaining refrigerants will boil at a higher temperature.

- At 23°F, the next refrigerant in the composition boils away, changing the composition and concentration again.

- At 28°F, the final refrigerant boils away. The entire refrigerant blend evaporates into a gas, and the boiling point “glides” up to 28°F.

Bubble, Mid, & Dew Point

For refrigerants without a glide, it is simpler to design a system because the refrigerant boils at the same temperature throughout the operation. But with high-glide refrigerants, the equipment could be designed for either when the refrigerant starts to boil (evaporate), when it has partially boiled, or when it has fully evaporated.

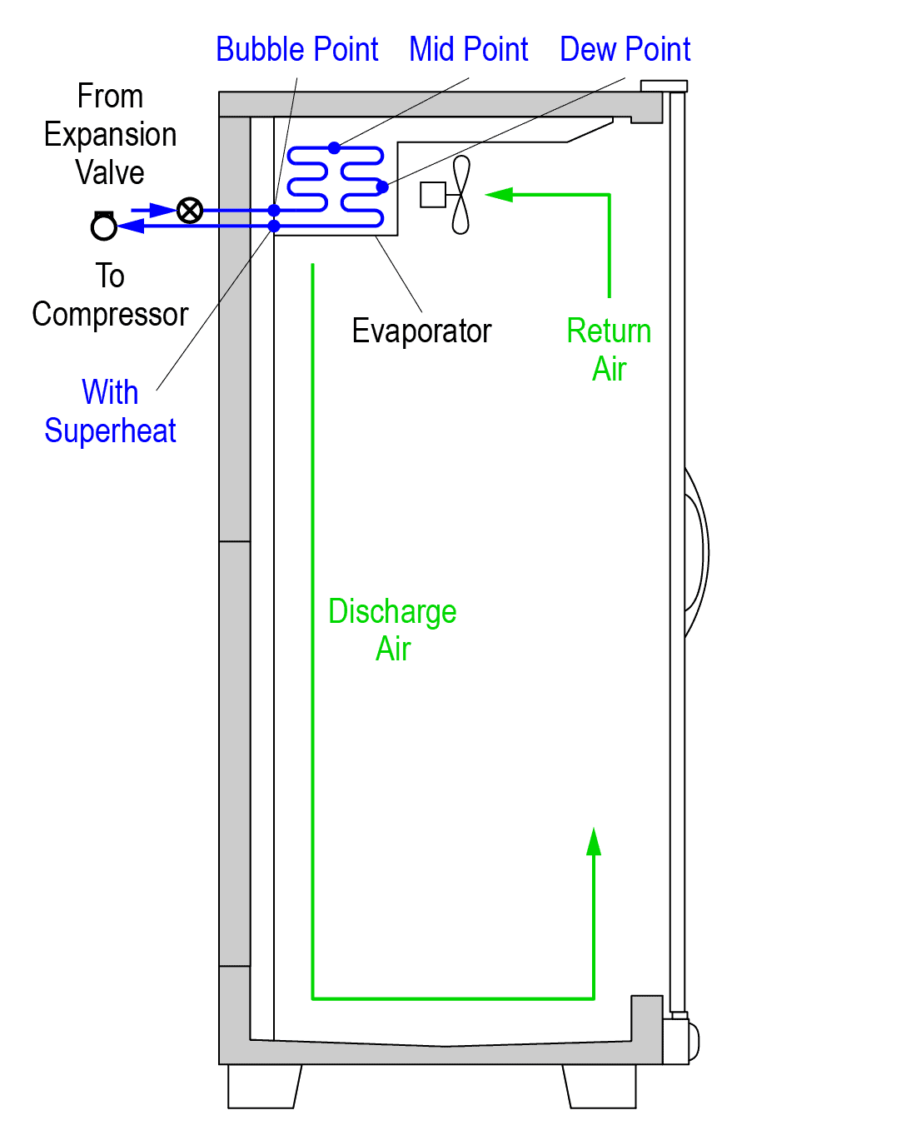

Refrigeration engineers and service contractors need to be familiar with the terms bubble point, mid point, and dew point.

- Bubble point: Liquid refrigerant starts to boil at this pressure and temperature in the evaporator.

- Mid point: Half of the liquid refrigerant has boiled away to a gas.

- Dew point: The last of the liquid refrigerant boils away.

To remember these terms, think about how a liquid bubbles as it boils or how dew forms in the morning when water vapor condenses.

The terms bubble point and dew point need to be understood and applied when discussing high-glide refrigerants. If the equipment does not specify bubble or dew point, the contractor could operate it incorrectly. Bubble point and dew point can be very different, as seen in the previous example (18°F versus 28°F). Warning: If there is ambiguity about whether equipment was designed for dew point, mid point, or bubble point, ask the equipment manufacturer. Do not make assumptions and risk damaging the equipment by running it incorrectly.

Consider This

There are two things worth mentioning to further our discussion. First, the terms bubble, mid, and dew point must be applied differently when talking about condensers on the high side of the refrigeration cycle. The condenser starts at the dew point as vapor refrigerant begins to condense into a liquid, and it finishes at the bubble point as the vapor refrigerant completely condenses into a liquid.

Second, there are also low-glide refrigerants. Low-glide refrigerant blends do not separate as much as high-glide refrigerants when they boil, so the bubble point and dew point are closer together. However, even a small temperature difference affects how equipment is sized and used. It is still important to know the difference between bubble point and dew point for any refrigerant that has a temperature glide.

These are just the basics about temperature glide, but hopefully you can already understand the importance of knowing the terms bubble point, mid point, and dew point.

Using High-Glide Refrigerants

High-glide refrigerants are more complex because of the glide. Why would someone want their system to use high-glide refrigerants? These blended refrigerants were developed specifically to have less of an impact on the environment. Older synthetic refrigerants had high ozone depletion potential (ODP) and high global warming potential (GWP). Refrigerant manufacturers have developed high-glide refrigerants to have low or no impact on the ozone layer and global warming. High-glide refrigerants are gaining popularity because of this, but the glide leads to some new challenges when designing and servicing a refrigeration system.

Have questions? Contact us and ask for our Director of Regulatory Compliance & Refrigeration Technology.