Refrigeration is changing—fast. As environmental regulations tighten and companies seek more sustainable options, A2L refrigerants are stepping into the spotlight. Just as life in the desert has adapted to thrive under pressure, these new refrigerants are the refrigeration industry’s response to a changing climate and regulatory environment. These newer refrigerants are making it easier for businesses to stay ahead of regulations and reduce their carbon footprint.

So, what exactly are A2Ls?

Let’s break it down.

CO₂ refrigeration systems are becoming the go-to modern, eco-friendly solution because environmental regulations are tightening, and as a result, energy efficiency is taking priority in commercial and industrial refrigeration operations. However, CO₂ refrigerant systems aren’t just a drop-in replacement for traditional refrigerants. Instead, they come with a unique set of considerations that ultimately impact performance, reliability, and long-term ROI.

In this blog, we’ll break down the basics of CO₂ (carbon dioxide) refrigeration in clear, practical terms. Whether you’re upgrading equipment, building a new facility, or exploring sustainable refrigeration options, this guide will help you understand what makes CO₂ systems different—and how to maximize their potential in your operation.

Why Choose CO₂ as a Refrigerant?

CO₂, also known as refrigerant R-744, is gaining momentum in the refrigeration industry for good reason:

- Low Environmental Impact: CO₂ has a Global Warming Potential (GWP) of just 1. In contrast, traditional refrigerants like R-404A have a GWP over 3,900.

- High Energy Efficiency: In the right conditions, CO₂ systems can outperform conventional refrigeration systems, particularly in cooler climates.

- Regulatory Compliance: CO₂ systems future-proof your facility by aligning with evolving environmental and refrigerant phase-down regulations.

However, CO₂ is not without its challenges. Specifically, system design, pressure management, and climate adaptability require careful consideration.

Key Differences: How CO₂ Refrigeration Systems Operate

CO₂ refrigeration systems function differently than traditional systems, and understanding these differences is key for informed decision-making.

-

Higher Operating Pressures

- CO₂ operates at much higher pressures than other refrigerants. Although this might sound alarming, today’s systems are built with specialized components designed to handle these conditions safely and reliably. Proper engineering and installation are essential.

-

Two Modes of Operation: Subcritical and Transcritical

- Subcritical Mode: In cooler climates or during colder months, CO₂ behaves like traditional refrigerants—operating at manageable pressures with efficient heat exchange.

- Transcritical Mode: In warmer environments, CO₂ enters a supercritical state, where it no longer behaves as a typical liquid or gas. This mode requires more advanced system controls and heat rejection strategies to maintain efficiency.

-

Unique Thermodynamic Properties

- CO₂ has a triple point and critical point that impact system design. These characteristics influence how heat is removed and, furthermore, how pressure is managed across the system, particularly in variable climates.

- Triple Point: The temperature and pressure where CO₂ can exist as a solid, liquid, and gas.

- Critical Point: The temperature where CO₂ becomes a supercritical fluid.

Commercial Refrigeration and the AIM Act

The American Innovation and Manufacturing (AIM) Act, enacted in December 2020, has brought significant changes to the commercial refrigeration industry. As we navigate through 2025, the first set of restrictions under the AIM Act are now in effect. These restrictions aim to phase down the production and consumption of hydrofluorocarbons (HFCs) by 85% by 2036. Consequently, these regulations are crucial for reducing greenhouse gas emissions and transitioning to more environmentally friendly refrigerants.

Technology Transition Rule

One of the key aspects of the AIM Act is the Technology Transition Rule, which impacts the repair and servicing of refrigerated display cases. The rule specifies that repairs are permissible unless they result in the creation of a new system. Therefore, while existing display cases can continue to operate and be serviced, certain extensive repairs may be restricted. For instance, assembling a system for the first time from used or new components, increasing the cooling capacity of an existing system, or replacing 75% or more of evaporators and 100% of the compressor racks, condensers, and connected evaporator loads are considered new installations. Importantly, these replacements are cumulative—meaning all prior repairs are counted toward the threshold when evaluating whether a system has effectively been replaced.

Ensuring Compliance

Understanding these repair restrictions is essential for businesses to ensure compliance and avoid potential penalties. As we move forward, staying informed and adapting to these regulations will be key to maintaining operational efficiency and environmental responsibility. This blog will help navigate the repair restrictions of refrigerated display cases.

Last month, we discussed the ways in which industrial and commercial refrigeration systems can achieve greater energy efficiency using modern components.

This month, we will delve into the advancements in commercial reach-in freezers and coolers, commonly known as refrigerated display cases within the industry. We will explore how these units have been optimized for efficiency and effective cooling with the integration of the latest refrigeration technology.

As energy costs rise, regulations evolve, and consumer demand for environmentally friendly solutions increases, evaluating your current commercial or industrial refrigeration system for a potential upgrade increases in importance. When considering an upgrade, several factors – such as the current condition of your equipment, maintenance costs, energy efficiency, and refrigerant type must be evaluated. Each of these factors play a role in determining the cost effectiveness of an upgrade.

Now that we have crossed into 2025, the first restrictions of the American Innovation and Manufacturing (AIM) Act are now in effect. The AIM Act of 2020 allows the EPA to restrict the production, import, and use of hydrofluorocarbons (HFCs). HFC refrigerants have a high global warming potential (GWP) and are being phased down by 85% through 2035.

The Refrigerants allowed by the AIM Act are not direct substitutes for HFC refrigerants. Refrigeration systems require different components, piping and programming with each refrigerant. The performance of refrigeration systems is influenced by the external ambient temperatures.

Equipment installed before restrictions go into effect are allowed to maintain operation throughout their useful life. This includes service, parts, and refrigerant. However, the availability of each is dependent on the manufacturer.

Retrofitted equipment and new installations have their own regulations and definitions. Retrofitted equipment, replacing at least 75% or more of the evaporators and 100% of the compressor racks, condensers, and connected evaporator loads of an existing system, will need to follow the restrictions for a new installation. For more information on the AIM Act and state regulations, visit our Refrigerant Regulations webpage.

Our Legacy and Commitment to Community and Family

On June 8, 1961, George Johnson, Duke Wegner, and K. Hirata founded Zero Zone in a rented barn in Pewaukee, Wisconsin. Since then, their dedication to customer satisfaction, through personalized support and customizable options, has fostered a legacy of trust for over six decades. Consequently, today, we remain committed to upholding these values while we continue to serve our community.

At Zero Zone, we prioritize the care and support of our family. Recognizing the importance of people, we place support and empathy at the heart of our culture. Whether you are an employee, customer, or partner, Zero Zone responds to your needs with attentiveness and care.

Addressing the Skilled Trade Workforce Shortage

The skilled trade workforce shortage is becoming increasingly critical as the American workforce ages and new technologies emerge in the industrial and commercial refrigeration industries. Consequently, training a new generation of workers has become essential. To tackle this issue, Zero Zone collaborated with Apprentice Now to create an apprenticeship program aimed at training new technicians.

The 14 candidates selected for the program completed their 10-week training on December 3. Although they have graduated from the program, these students will continue their hands-on education as they advance in their careers.

Zero Zone helped train these technicians without the expectation that students would take a position with us. They will have the opportunity to apply for a position with Zero Zone or other companies within the industry. Apprentice Now aids the new technicians with placement in open roles throughout the industry. Recognizing the demand for technicians in the industrial and commercial refrigeration industry, we see this partnership as a proactive step.

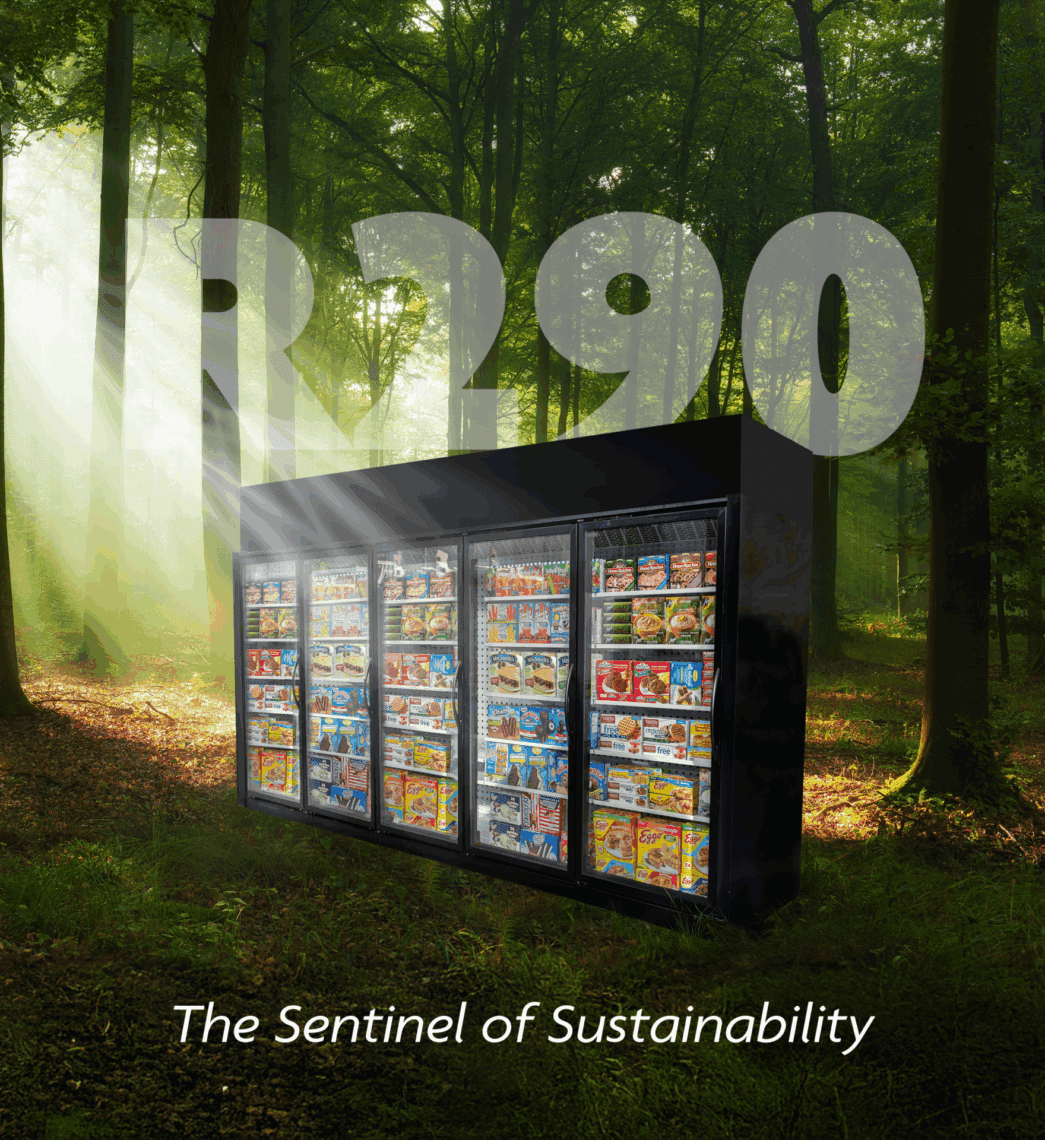

AIM Act Refrigerants: Driving Sustainable Business Practices

AIM Act Refrigerants are rapidly gaining priority as rising energy costs, evolving regulations, and increasing consumer demand for environmentally friendly solutions drive change. Consequently, sustainable business practices have become essential. In the refrigeration industry, the choice of refrigerant directly affects both energy costs and regulatory compliance. Therefore, this blog will explore the advantages and disadvantages of low-global warming potential (GWP) refrigerants, including Natural and Hydrofluoroolefin (HFO) options.

Zero Zone Reliability in Addressing Water Scarcity

In 2002, a severe drought agonized 33% of the contiguous United States. Crops and pastures suffered, wells ran dry, and reservoirs drained. In Colorado, over 3 million people lost their water security. Consequently, authorities implemented water restrictions. Residents limited outdoor lawn watering, which accounted for half of annual residential water use, to once a week and scheduled it by address numbers. Additionally, residents could not fill swimming pools during one of the warmest summers on record.

Planning for Future Droughts

After the drought broke, planning for the next one became a priority. An expansion project began on Colorado’s Gross Reservoir Dam, located in Boulder County, to prevent future water scarcity. The project aims to raise the dam by 131 feet, totaling 471 feet, to increase the reservoir’s capacity by 25 billion gallons of water. After the expansion, the dam will be three times its current size and the tallest concrete dam in Colorado.

Zero Zone’s Role in the Project

Although this project presents many challenges, one in particular caught the attention of Zero Zone: the heat concrete produces as it cures. Zero Zone reliability ensures that the project addresses this issue effectively, contributing to the overall success of the dam’s expansion and the prevention of future water scarcity.