Flexibility and Durability of Hybrid™ Merchandisers

The Hybrid™ merchandiser offers the flexibility of a self-contained display case while maintaining the durability and sales capability of those in large supermarkets. Each Hybrid™ merchandiser inherits the traits of its remote counterpart and has all the necessary refrigeration components mounted on top of the display case. These cases require minimal effort to install. After connecting the remote condensing unit to the display case, they are ready to be energized for operation. With medium- and low-temperature options, you can display beverage, bakery, dairy, deli, floral, frozen food, meat, produce, or seafood products in an environment that will keep them fresh.

Benefits for Stores of Any Size

Zero Zone Hybrid™ merchandisers provide benefits for a store of any size. They allow small format stores to effectively and efficiently use their floorspace for merchandising products rather than taking up valuable real estate for the refrigeration system. Additionally, large format retailers can add a Hybrid™ merchandiser to the sales floor without increasing the installed system’s load or the need for additional refrigeration piping.

A walk-in cooler turns into an oasis during the summer months. While this may bring you relief, it adds stress to your industrial or commercial refrigeration system. The efficiency of any refrigeration system drops as the ambient temperature increases. Pressure within the system also increases, putting strain on the entire system. For areas with warmer climates, this happens for a longer period of time during the year. There are many ways to mitigate stress and heat in your system, but which one works best for your application?

The Highlight Merchandiser® is a durable display case that exudes classic charm. This workhorse not only offers a generous packout but also provides a spectacular, full view of your product. Whether you need to protect frozen food, ice cream, beverages, dairy, deli items, meat, ice, or produce, the Highlight Merchandiser® rises to the occasion. Moreover, its robust construction ensures longevity, while its elegant design enhances the visual appeal of any retail space. Thus, the Highlight Merchandiser® seamlessly combines functionality and aesthetics, making it an ideal choice for showcasing a wide variety of products.

Zero Zone reliability has built a trust with customers across North America. This trust grew from our small town in Wisconsin by selling to local retailers, such as Webster’s Marketplace. When Webster’s Marketplace expands, they choose Zero Zone for their refrigerated display cases. DuWayne Wichman, one of the store directors, has said in an interview, “I can’t say enough good things about [Zero Zone refrigerated display cases].” Inside Webster’s Marketplace, you’ll find Zero Zone display cases in operation from 1984, 2005, 2015, 2017, and 2024.

The Reveal Merchandiser®

The Reveal Merchandiser® aligns with the diversity of your product by offering a variety of features. Specifically, it provides options for beverages, dairy, deli, meat, and produce. Additionally, the multitude of lighting, shelf, and accessory choices empowers you to take control of creative merchandising.

The Lineup

Before we can accessorize a display case, we have to know what we are working with. Zero Zone has four models for the Reveal Merchandiser® display case.

Industrial Refrigeration Solutions

Industrial Refrigeration Solutions differ significantly from retail refrigeration. For starters, they operate at different stages in the Cold Chain, which is a temperature-controlled supply chain for perishable goods. This supply chain begins with storage, processing, or both. Next, it moves to transportation, and finally arrives at the distribution stage.

Retail Refrigeration

Retail refrigeration exists within the distribution step. Think of places that need refrigeration and have a checkout counter. These systems are designed to keep products cool and fresh for consumers at the point of sale.

Industrial Refrigeration

In contrast, industrial refrigeration operates before the retail level. These systems are crucial for maintaining the quality and safety of products during storage and processing, ensuring that they remain fresh throughout transportation and up until they reach the retail stage.

Common Applications

Before we delve into the specifics of industrial refrigeration, let’s explore some common applications where Zero Zone systems have been used. These applications highlight the versatility and effectiveness of industrial refrigeration solutions in various settings.

The Zero Zone Crystal Merchandiser® is more than a display case to keep your products cold, it is used to show off your product’s best features. Crystal Merchandiser® applications include floral displays, produce, dairy, deli, wine, beverages, ice cream, and frozen foods. The versatility of the Crystal Merchandiser® applications does not end with what can be displayed, but how its contents can be displayed.

What is a Small Format Store?

A Small format store typically measures less than 25,000 ft² and requires less than 30 tons of refrigeration capacity. These stores often include convenience stores, small grocery stores, and pharmacies. Due to their size, small format stores lack the space or lease agreements needed to install the large rack units favored by large-format retailers. Additionally, organizing small format stores to fit display cases presents another complication.

Why CO2?

Carbon dioxide (CO2) as a refrigerant offers several advantages:

- It significantly reduces the environmental impact and plays a crucial role in combating climate change.

- CO2 is the gold standard for ozone depletion potential (ODP) at 0.

- It has a global warming potential (GWP) of 1.

Many countries, including the US, are phasing out high-GWP synthetic refrigerants and enforcing stricter environmental regulations. Embracing CO2 ensures compliance with these evolving regulations, avoiding penalties and legal complications.

CO2 is nonflammable, nontoxic, and a low-cost refrigerant. The recent advent of high-pressure, iron-impregnated copper has allowed the transition from traditionally stainless-steel piping to familiar brazed copper piping, further improving value and simplifying repairs.

Is CO2 Right for Your Small Format Store?

CO2 is also a low-cost refrigerant. Most synthetic refrigerants can cost upwards of $20 per lb, whereas the current price of CO2 is around $3 per lb. CO2 systems require smaller copper pipes than other refrigeration systems, which decreases installation costs. Additionally, CO2 systems have excellent energy efficiency, minimizing operational costs. Its high density and low viscosity increase coil efficiency, allow for smaller line sizes, and take advantage of smaller compressors.

Although everyone with a CO2 system can enjoy its benefits, small format stores can go a step further. Since small format refrigeration systems require less refrigerant, they do not need heat removal through air conditioning. This means the heat reclaim can be used for space heating, dehumidification, commercial kitchens, and restrooms.

Zero Zone understands that one size does not fit all. Our Genesys™ Natural Refrigeration Systems can be tailored for small format stores with the following products.

Indoor Parallel Systems

Outdoor Parallel Systems

Distributed Refrigeration Systems

Real World Examples

Here are some case studies of using Zero Zone’s CO2 Genesys™ Natural Refrigeration Systems in small format stores:

Small grocery store in Stapleton, CO

- Zero Zone completed this project using an indoor parallel system that can operate on a mezzanine in a mechanical room in a 5B climate zone. It has a remote adiabatic gas cooler, negating the need for air conditioning. The design pressure is 120 bar on the high side and 45 bar on the low side.

Small format store in Islandia, NY

- This store is located in a 4A climate zone and home to one of Zero Zone’s outdoor parallel roof-mounted rack systems. This system has a remote air-cooled gas cooler and a design pressure of 120 bar high side and 90 bar low side.

Convenience Store in Dayton, MN

- Zero Zone also has an outdoor parallel system mounted on the roof in a 6A climate zone. This system measures 120 bar on its high side and 45 bar on its low side. This location also uses the heat reclaim for heating the backroom air coil and water.

A common myth surrounding CO2 as a refrigerant is that it can only be used in certain climates. This is true only for certain types of CO2 systems. Transcritical CO2 systems can only be used in cooler climate zones. Subcritical CO2 systems can be used in any climate zone. At Zero Zone, we have a solution for natural refrigerants in any climate.

Are You Ready for Zero Zone’s Genesys™ CO2 System?

To start a project or learn more about how Zero Zone can help, contact one of our sales representatives.

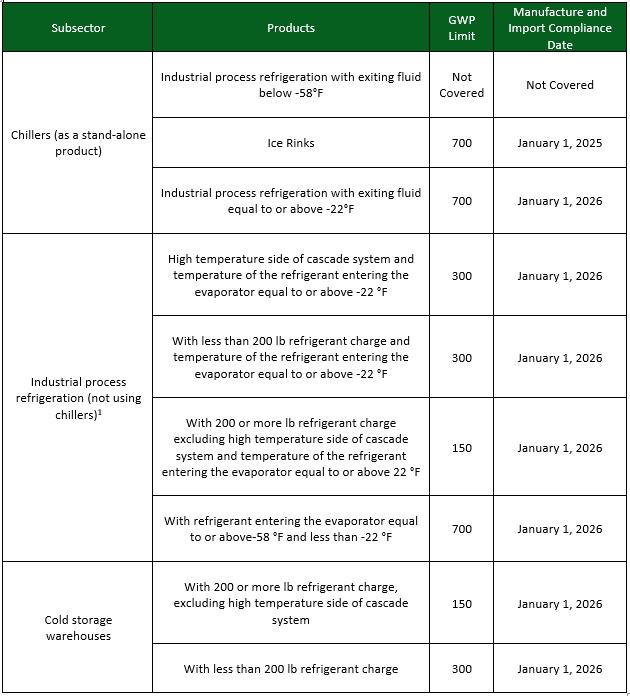

What is the AIM Act?

The American Innovation and Manufacturing Act (AIM Act) was passed in 2020 by bipartisan support in the U.S Congress as the United States joined the global movement to reduce human impact on climate change. The AIM Act directs the U.S. Environmental Protection Agency (EPA) to oversee the phasedown of HFC refrigerant production and consumption in an effort to transition to alternative refrigerants. The AIM Act includes a phasedown schedule that began in 2022 and continues to 2036.

The new rule prohibits the manufacture and import of self-contained products that use hydrofluorocarbons (HFCs). The rule also prohibits the sale, distribution, and export of products three years after the manufacture and import restriction. Finally, it prohibits the installation of new refrigeration air conditioning and heat pump (RACHP) systems that contain HFCs. The compliance dates of these new rules vary based on sector and subsector.

Who does the AIM Act refer to?

The final rule states, “Entities that manufacture, import, export, sell, distribute, or install systems or products that use HFCs in refrigerants and air-conditioning equipment systems, heat pumps, foams, and aerosols may be affected by this new rule. Restrictions apply to original equipment manufacturers, product distributors, retailers, and companies that direct the installation of new RACHP systems.”

Important definitions

The final rule makes a distinction between products and systems. Certain products and the installation of certain systems have different restrictions.

A product is functional upon leaving a factory. Examples of products include self-contained refrigerators and self-contained ice machines. The EPA is restricting the sale, distribution and export of products containing higher-GWP HFCs three years after the manufacture and import restriction dates.

A system is assembled and charged in the field using multiple components. An example of a system is a supermarket refrigeration system that include a centralized compressor room. Components include equipment such as compressors, condensers, and display cabinets. There is not a restriction on the manufacture, import, sale, distribution, or export of components that are used to repair existing systems.

When will the phasedown start?

Industrial Phasedown

Retail Phasedown

Notes:

Notes:

- Industrial Process Refrigeration (IPR) systems are used to cool process streams at a specific location in manufacturing and other industrial processes (e.g., chemical, pharmaceutical, petrochemical, and manufacturing industries).

- Refers to the Zero Zone Hybrid™ display cases and rack condensing units (Edge XT).

- Refers to Zero Zone’s Highlight®, Crystal®, and Reveal® display cases and their associated systems.

Why was the AIM Act proposed and passed?

The AIM Act addresses petitions from industry, environmental organizations, and state governments to restrict the use of HFCs. The EPA has estimated the potential benefits of this rule will provide savings to American consumers and industry through energy efficiency and lower-cost refrigerants. The EPA stated that this rule will also result in greenhouse gas emissions reduction benefits.

- EPA estimations:

- Emission reduction of 876 million metric tons of carbon dioxide equivalent through 2050.

- $50.4 billion in climate change mitigation benefits

- $4.5 billion in cost savings to consumers and businesses driven by the lower cost of HFC substitutes and increased energy efficiency of lower-GWP refrigerants

For our customers

This rule does not restrict Zero Zone customers from using their existing refrigeration systems. The EPA has allowed an existing system to continue its operation to the end of its useful life. The systems may be serviced and repaired throughout their use, including replacing components. Components needed for repair are allowed to continue being manufactured.

For new installations, the equipment needs to be charged before the compliance dates. The following actions are considered a new installation:

- Assembling a system for the first time from used or new components;

- Increasing the cooling capacity, in BTU per hour, of an existing system; or

- Replacing 75 percent or more of evaporators (by number) and 100 percent of the compressor racks, condensers, and connected evaporator loads of an existing system.

Into the Future: Refrigerant Management

Although a system can be serviced until the end of its useful life, the refrigerants used to recharge it will become scarce as production slows. The costs of synthetic refrigerants are expected to rise. The EPA is currently working on a standard for refrigerant reclamation and requirements for reclaimed HFC refrigerants. They are proposing that as of January 1, 2028, reclaimed refrigerant must be used when servicing and/or repairing refrigerant-containing equipment. This includes supermarket systems and stand-alone retail food refrigeration.

If you have questions about these regulations, please contact Zero Zone and ask to speak to our Director of Regulatory Compliance & Refrigeration Technology, Bruce Hierlmeier.

How can Zero Zone Help?

At Zero Zone, we’ve always been green. Zero Zone offers sustainable refrigeration solutions with Genesys™ Natural Refrigeration Solutions. If you want to learn about our offerings and plans for these new regulations, contact our sales team or visit Zero Zone’s Genesys™ Natural Refrigeration Solutions webpage.

View the infographics for our Retail and Industrial customers for a summary of important facts and dates.

Refrigeration Load Requirements & Challenges

Private label juice manufacturer Citrus Systems, Inc. specializes in pasteurizing an extensive line of juices and fruit drinks. The business provides juice to local dairies, grocery stores, and institutional customers. Their success and future contracts led them to build a new facility that is twice as large as their previous location. Consequently, this expansion presented several challenges for their refrigeration needs.

Large Capacity Needed

To accommodate their increased production, Citrus Systems required:

- 2 pasteurizers

- 6 packaging lines

- 18 blending and storage vessels

- Over 560,000 cubic feet of storage

- Doubled square footage from the previous facility

- A system that follows precise HACCP food safety guidelines from the FDA

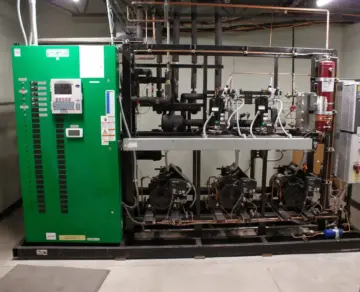

The Zero Zone Refrigeration Solution

To meet these demands, Zero Zone provided three refrigeration systems:

- A low temperature rack offering 82 tons of cooling at -23°F

- A medium temperature rack providing 124 tons of cooling at +20°F

- A 4-circuit chiller delivering 240 tons of cooling at +18°F

Additionally, Zero Zone designed and built a package rack system to be installed on-site. To ensure food safety, the system includes remote monitoring and diagnostics.

The refrigeration systems are designed to provide trouble-free, energy-efficient operation for Citrus Systems’ production process. Zero Zone incorporated features and technology tailored to the needs of pasteurization plants, such as multiple chilling circuits, industrial PLC controls, and evaporative condensing with variable speed fan control. Furthermore, a heat reclaim system off the compressor discharge circuit reduces both electric and natural gas demand by repurposing heat for hot water used throughout the production facility.

Guaranteeing that the system always maintains the correct temperature is essential for Citrus Systems’ HACCP program. To monitor operations and communicate any alarm conditions, Citrus Systems implemented a remote diagnostics system connected to the refrigeration equipment. Consistency and dependability are crucial in the pasteurization and food processing industries to protect the quality of the final product.

A Satisfied Customer

Thomas E. Boehland, founder and president of Citrus Systems, takes great satisfaction in how everything came together, describing the equipment as “a work of art.” He praised the Zero Zone team: “You can tell that there is a lot of pride in what they put together. It isn’t just a bunch of refrigeration components cobbled together on-site to get the job done. It’s a nice package, and you can tell just by looking at it. The factory people take pride in it and even sign off on the equipment with each individual person putting their names to it. You don’t see that very often these days.” Boehland concluded by saying, “I’ve put my faith in Zero Zone to do what we need to be done.”

Contact our sales team to start on your next refrigeration journey.

Read more in the full case study: “An Industrial Work of Art.”

Notes:

Notes: