Concrete Evidence of Zero Zone Reliability

Zero Zone Reliability in Addressing Water Scarcity

In 2002, a severe drought agonized 33% of the contiguous United States. Crops and pastures suffered, wells ran dry, and reservoirs drained. In Colorado, over 3 million people lost their water security. Consequently, authorities implemented water restrictions. Residents limited outdoor lawn watering, which accounted for half of annual residential water use, to once a week and scheduled it by address numbers. Additionally, residents could not fill swimming pools during one of the warmest summers on record.

Planning for Future Droughts

After the drought broke, planning for the next one became a priority. An expansion project began on Colorado’s Gross Reservoir Dam, located in Boulder County, to prevent future water scarcity. The project aims to raise the dam by 131 feet, totaling 471 feet, to increase the reservoir’s capacity by 25 billion gallons of water. After the expansion, the dam will be three times its current size and the tallest concrete dam in Colorado.

Zero Zone’s Role in the Project

Although this project presents many challenges, one in particular caught the attention of Zero Zone: the heat concrete produces as it cures. Zero Zone reliability ensures that the project addresses this issue effectively, contributing to the overall success of the dam’s expansion and the prevention of future water scarcity.

Project Overview

Zero Zone Reliability in Concrete Mixing Process

Adding ice to the concrete mixing process ensures the pour temperature meets the dam engineer’s specifications. Temperatures as low as 50°F may be necessary. Lower pour temperatures reduce the likelihood of cracking during the curing process. Ice offsets the heat of hydration and friction caused by the mixing process when chilled water alone cannot achieve the required temperature.

Meeting the Cooling Demand

To meet the cooling demand, 250 tons of ice per day are needed. This involves pumping reservoir water to the icemaking system, storing the ice, and then conveying it to the concrete batching system. After mixing the concrete, a conveyor transfers it to the pour site. The contractor designing the project, TRJ Refrigeration of Oxnard, California, chose Zero Zone to design a rack system that provides refrigeration to part of the icemaking system.

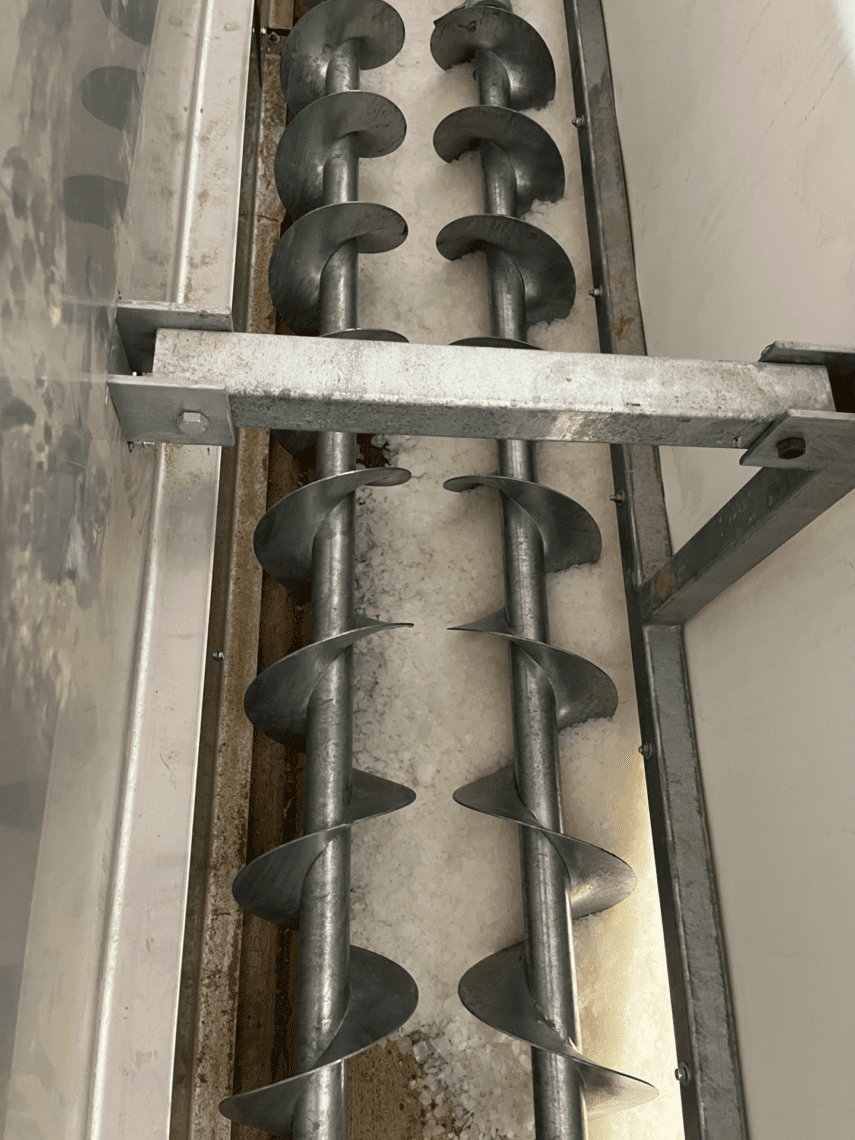

Zero Zone’s Role in Ice Production

A pump pulls water from the reservoir, and the refrigeration system freezes it before it reaches a conveyor. The conveyor brings the ice to the concrete, spreading it evenly to lower the concrete’s temperature. The current refrigeration system could not meet the project’s demand for ice. Therefore, the project owner selected Zero Zone to integrate another system to increase ice production.

Zero Zone reliability ensures that the project addresses the cooling needs effectively, contributing to the overall success of the concrete mixing process and the prevention of cracking during curing.

Challenges of the Project

The Zero Zone Team

Zero Zone Reliability in Installation and Startup

Dallas Schumann, Field Service Technician Supervisor, assisted with the installation and startup. He mentioned, “We had to walk into the building with the router to use the phone, so we couldn’t talk to the engineers while we were by the system. The installation went smoothly, and we only needed to call for programming information.” Zero Zone reliability ensures that our products are designed with ease of installation in mind. Our team is on-site for each installation to provide a worry-free startup, even in the most unique applications.

Safety Training and Practices

Due to the unpredictable nature of the construction site, Zero Zone technicians participate in a mandatory safety training course. The video describes the hazards they face and the safety plan for each. The combination of Zero Zone safety practices and on-site training results in an injury-free installation.

Commitment to Quality and Safety

Despite the commute being almost an hour one way, the team shows up each day ready to work. They remain aware of safety concerns and focused on providing a quality startup. The system installed at the Gross Reservoir Dam was finished on time and had a flawless startup.

With Zero Zone reliability and dedication to safety and quality, we ensure successful installations and startups, even in challenging environments.

Zero Zone Solutions

Zero Zone Reliability in Cooling Systems

The Zero Zone OPS system boasts a cooling capacity of 720,000 Btu/h, achieved with six reciprocating compressors. A semi-hermetic seal protects the compressors from debris during operation, ensuring longevity and reliability. Additionally, a panel-mounted CPC E3 controller manages the system, providing precise control and monitoring.

Effective Heat Dissipation

The construction site experiences ambient air temperatures averaging 80°F during its hottest month. Consequently, the air-cooled condenser effectively dissipates heat from the system, maintaining optimal performance even in challenging conditions. Zero Zone ingenuity ensures that basic components operate efficiently in unique applications.

Custom-Engineered Systems

Zero Zone custom-engineered systems offer flexibility to meet your unique needs. The ease of installation and maintenance guarantees that the system starts quickly without complications and remains operational. Zero Zone reliability ensures that your cooling system performs consistently, providing peace of mind and exceptional performance.

If you are interested in a Zero Zone refrigeration system, visit our products page, or contact a sales rep today.