Do It Right, Pay Less Later: The Zero Zone Advantage

In 1961, tucked into the rolling countryside of Pewaukee, Wisconsin, three refrigeration experts—George Johnson, Duke Wegner, and K. Hirata—converted a dairy barn into a workshop. An example in Midwest practicality. With a few tools, a lot of know-how, and a shared belief that refrigeration could be done better, they got to work. That barn became the birthplace of a company built on ingenuity—where resourcefulness, grit, and hands-on problem-solving weren’t just values; they were the business plan.

And it worked.

Built from the Ground Up, Staying Close to Home

Locally Sourced, Globally Minded

Even as Zero Zone serves customers across the country and beyond, our supply chain remains proudly regional. By prioritizing Midwest-based suppliers, we reduce environmental impact, support local manufacturing, and—true to our roots—keep things practical.

But local sourcing isn’t just about geography. It’s about Total Cost of Ownership (TCO).

Why Local Matters:

- Reduced Transportation Costs

Shorter distances mean lower fuel expenses, fewer warehousing steps, and no international shipping headaches. - Improved Efficiency and Control

Local suppliers offer faster, more predictable delivery times and easier communication. That means fewer production delays and better quality control. - Enhanced Supply Chain Resilience

Regional sourcing helps us avoid global disruptions and respond quickly to changing needs. With most suppliers located within a day’s drive, weather-related disruptions are minimal. Flexibility isn’t a luxury—it’s a necessity. - Cost Efficiencies That Stick

A streamlined, local supply chain reduces complexity and hidden costs. Shorter lead times also mean lower inventory carrying costs—another win for long-term value.

Our Supplier Footprint

- 40% of sourcing comes from suppliers in Wisconsin

- 64% is sourced from the Midwest

- 97% sourced from the United States

See how our regional sourcing supported 99.73% on time delivery for over 1,000 projects by clicking the button below.

Our 5 Locations

- Ramsey, MN

- This site builds the backbone of our commercial and industrial refrigeration systems: parallel racks, distributed systems, and high-performance solutions. It also leads our innovation in natural refrigerants and energy-efficient designs—aligning performance with sustainability.

- North Prairie, WI

- Our headquarters brings together engineering, leadership, marketing, and manufacturing for our display cases under one roof. Collaboration flows naturally across teams, making this site the strategic core of both product innovation and workforce development.

- Waukesha, WI

- Minutes from North Prairie, this facility focuses on panel foaming and open multi-deck display cases. Its close coordination with nearby campuses boosts production agility and helps us meet the evolving needs of national retailers.

- Mukwonago, WI

- Our Mukwonago facility ensures products arrive on time and in prime condition. Integrated tightly with nearby manufacturing sites, it’s the final stop before Zero Zone equipment heads out to customers—backed by rigorous quality checks and shipment coordination.

- Dyersville, IA

- Dyersville specializes in assembling rack systems for cold storage and food processing. Each one is built to meet specific operational needs with precision and consistency. This facility reinforces our ability to deliver dependable refrigeration systems.

Come Visit Us

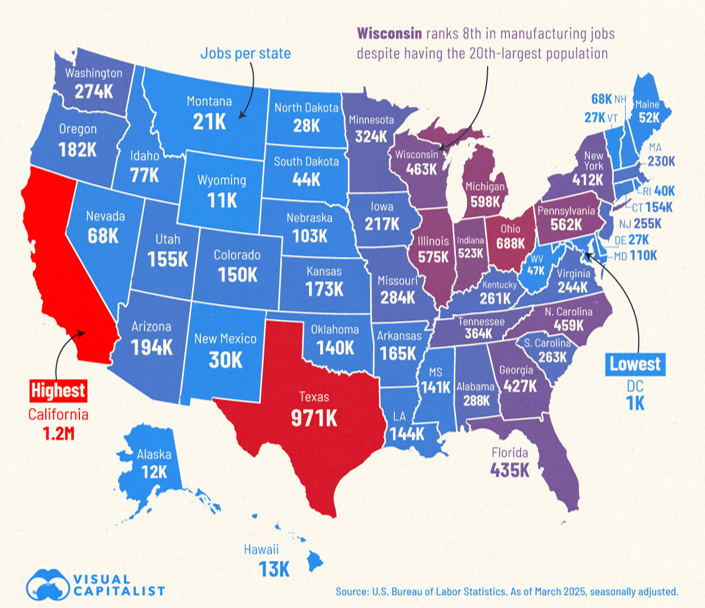

Manufacturing in Wisconsin

With over 7,700 manufacturing jobs for every 100,000 residents, Wisconsin leads the nation in manufacturing employment per capita. Despite being the 20th most populous state, Wisconsin ranks in the top 10 for total manufacturing jobs, outperforming states twice its size.

Why That Matters to You

When you partner with Zero Zone, you’re working with a manufacturer that operates in one of the most established industrial regions in the country. A region where proximity to suppliers, skilled labor availability, and logistical efficiency contribute to dependable lead times and consistent production.

The Zero Zone Advantage: Built to Last, Backed by Values

At Zero Zone, we don’t just build refrigeration systems—we build trust, reliability, and value into every weld, panel, and connection. From our roots in a converted dairy barn to our multi-state manufacturing footprint, we’ve stayed true to the principles that launched us: work hard, solve real problems, and never cut corners.

That mindset drives our approach to sourcing, training, and service. With most materials and partners close to home, we reduce lead times, minimize risk, and maintain tighter control over quality. It’s not just efficient—it’s cost-effective over the life of the system.

As the industry evolves, we continue to adapt. But our foundation remains the same: practical innovation, operational precision, and a commitment to delivering systems that perform reliably for years to come.

Whether you’re a contractor, retailer, or facility manager, we invite you to the Zero Zone experience—where responsiveness and trust are built into every solution.

To learn more, view our products page or contact us.