Don’t Panic, Prepare: The New Era of Refrigerant Regulations

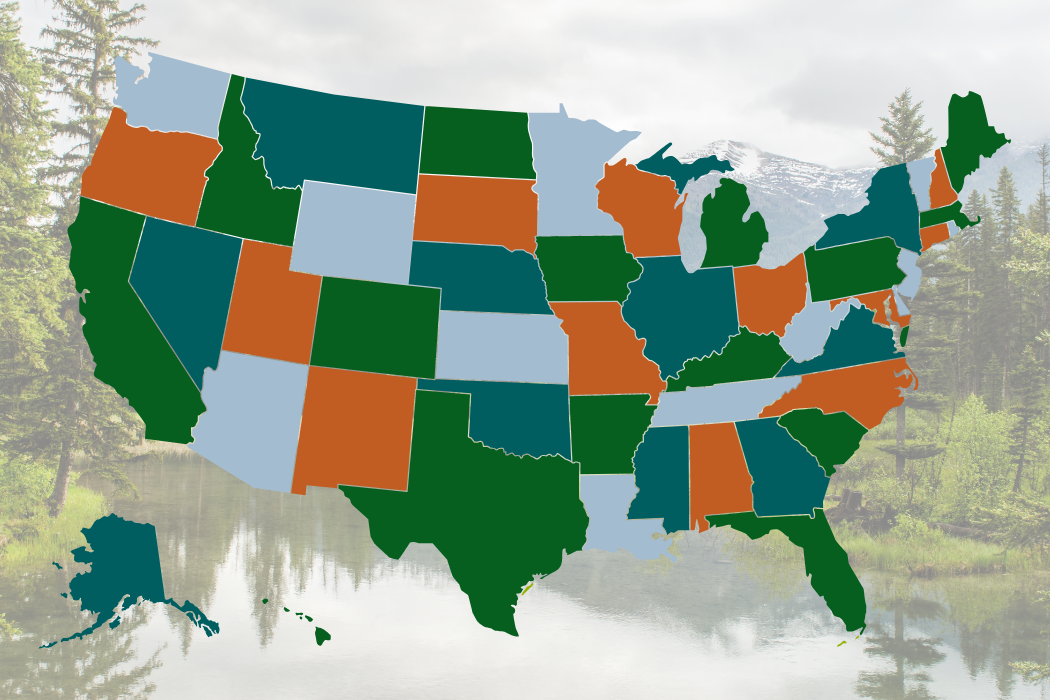

As federal, state, and international bodies intensify efforts to phase down hydrofluorocarbons (HFCs), the commercial and industrial refrigeration sectors must adapt to a rapidly changing regulatory landscape. State and local regulations are allowed to have requirements that exceed federal EPA regulations. California, Washington, and New York have finalized comprehensive regulations, while adhering to the AIM Act, governing the use of high-GWP refrigerants, leak detection and repair, and system transition timelines. The standard GWP metric typically reflects a 100-year time horizon, referred to as GWP100, when evaluating the climate impact of refrigerants.

Below is an overview of these evolving requirements and how they impact your operations.

California: CARB Regulations and Immediate Compliance Requirements

Key Takeaways from the CARB HFC Regulation:

- Bans on High-GWP HFCs: The use of refrigerants such as R-404A, R-507A, R-422D, and others are now prohibited in new and retrofit supermarket systems, remote condensing units, and stand-alone equipment.

- Currently, California allows the use of R-448 and R-449 in systems with 50 lbs of charge or less. Federal regulations from the EPA will supersede this in upcoming deadlines.

- California’s refrigerant regulations, enforced by the California Air Resources Board (CARB), include a provision that limits the total Global Warming Potential (GWP) charge a corporation can have across all its refrigeration systems. This means companies must track and potentially reduce the cumulative GWP of all refrigerants in use, not just individual system charges.

Applicability:

These rules apply to any person or entity involved in the sale, installation, use, or commerce of refrigeration substances within California. This broad applicability ensures that all stakeholders in the refrigeration industry comply with the new standards.

Leak Repair Requirements:

Leaks must be repaired within 14 days, with chronic leakers subject to system retirement or retrofit.

Recordkeeping:

Manufacturers and equipment operators must disclose refrigerant types and retain detailed sales, installation, and service records.

Penalties:

Non-compliance may result in substantial fines, especially for failure to report or falsify records.

Impact:

CARB’s enforcement strategy targets both upstream manufacturers and downstream end users, making robust documentation and staff training critical. CARB can audit the documentation, including equipment sales and refrigerant usage.

Washington: WAC 173-443 and Upcoming 2026 Prohibitions

Key takeaways from WAC 173-443:

- New commercial refrigeration systems, including retail food refrigeration and cold storage warehouses, with a full charge of more than 50 pounds of refrigerant are limited to a GWP of 150 or less. Retrofit refrigeration equipment within this category will be limited to a GWP of 150 or less on Jan 1, 2029.

- New industrial Process refrigeration excluding chillers with a full charge of more than 50 pounds of refrigerant are limited to a GWP of 750 or less. Retrofit refrigeration within this category will be limited to a GWP of 750 or less in 2029.

- New Ice rinks have been limited to a GWP of 150 and retrofit ice rinks to a GWP of 750 since January 1, 2024.

- The registration and documentation for refrigeration equipment has been mandatory since January 1, 2024.

New York: Part 494 Regulation and Long-Term Transition Strategy

The new regulations from New York took effect January 10, 2025. For equipment installations, the compliance deadline is January 1, 2026, by which time only A2L or natural refrigerants may be used. New York’s regulations adopt GWP20 values.

GWP20 of Common Refrigerants

Here is a quick reference for the 20-year Global Warming Potential of several commonly used refrigerants:

| Refrigerant | GWP20 |

|---|---|

| R-513A | 1,822.61 |

| R-454C | 579.75 |

| R-515B | 525.15 |

| R-744 (CO₂) | 1 |

| R-290 (Propane) | 0.02 |

| R-717 (Ammonia) | 0 |

Curious how GWP100 stacks up against GWP20 for common refrigerants? Click here to find out.

Key Takeaways from New York Part 494:

GWP Restrictions

- New retail food refrigeration facilities must comply with a GWP20 limit of 10 for systems with a refrigerant charge of 200 pounds or greater.

- Industrial process refrigeration chillers have a GWP20 limit of 2690

- Existing supermarket systems, remote condensing units, cold storage warehouses, and industrial process refrigeration systems with a refrigerant charge capacity of 200 pounds or greater must meet a GWP20 limit of 580.

- For existing systems with a refrigerant charge capacity of less than 200 pounds, the GWP20 limit is set at 943.

Recordkeeping and Reporting:

Enhanced recordkeeping and reporting requirements will be enforced to ensure compliance with the new standards. Companies must maintain detailed records of equipment sales and refrigerant usage, which can be audited by regulatory authorities.

Market Opportunities:

The regulations create opportunities for innovation in the refrigeration industry. Companies that develop and market low-GWP refrigerants and compliant refrigeration systems can gain a competitive edge in the market.

Refrigerant Management Program

The regulation establishes a Refrigerant Management Program (RMP) for owners or operators of commercial refrigeration equipment containing 50 pounds or more of refrigerant. This program requires businesses to register and label their equipment, conduct regular leak monitoring, and address any leaks promptly. The specific requirements and deadlines are based on the amount of refrigerant used:

- Large Equipment (1,500 lbs or more capacity): 1 June 2025

- Medium Equipment (200-1,499 lbs capacity): 1 June 2026

- Small Equipment (50-199 lbs capacity): 1 June 2028

- All new equipment: 1 June of the following year

Supermarket Refrigerant Program

Supermarket chains owning or operating 20 or more retail food facilities in New York (or 100 facilities nationwide) with systems containing 200 pounds or more of refrigerant must participate in the Supermarket Refrigerant Program. By January 1, 2035, these chains are required to transition their refrigeration equipment with more than 50 pounds of refrigerant to alternative systems using refrigerants with a GWP20 of 10 or less or to control leakage to a comparable emissions quantity. This program provides flexibility for compliance through a Transition Plan, which must be submitted to the DEC by January 1, 2027.

Grant Program

To support the transition, the DEC is developing a new grant program based on the successful supermarket refrigeration demonstration program with the North American Sustainable Refrigeration Council (NASRC) and the NYS Pollution Prevention Institute (P2I). This upcoming grant program will provide funding to food stores and food banks, prioritizing disadvantaged communities, to install refrigeration systems using natural refrigerants.

What this Means for You

- Audit Existing Equipment: Identify systems using banned or soon-to-be-banned refrigerants.

- Plan for Transition: Budget for retrofits, replacements, or conversions using compliant refrigerants like CO₂ or HFO blends.

- Review Recordkeeping Practices: Ensure service logs, refrigerant use, and leak history are up to regulatory standards.

- Train Technicians: Internal and third-party technicians should be up-to-date on state-specific leak repair and reporting rules.

- Monitor Incentive Programs: Stay informed about federal and state-level grant opportunities to offset retrofit and conversion costs.

Zero Zone has the Answers

Regulations from CARB, WAC, and New York’s DEC are reshaping the commercial and industrial refrigeration landscape. Proactive compliance not only mitigates risk but positions businesses to lead in sustainability and operational efficiency. Now is the time to future-proof your systems—before penalties, product availability issues, or missed incentives make compliance harder and costlier.

Contact a Zero Zone rep today to schedule a consultation and discover how we can support your compliance journey and drive innovation in your refrigeration systems.