Refrigeration Innovation: A Zero Zone Legacy

This month marks the 64th anniversary of Zero Zone. Since 1961, the company has focused on developing refrigeration systems that are efficient, reliable, and aligned with evolving industry needs. That focus continues today, with solutions designed to support energy savings, reduce maintenance, and maintain consistent product temperatures.

This blog highlights how Zero Zone’s technologies have contributed to commercial and industrial refrigeration—and how they continue to offer practical value.

Better Designs for Real-World Performance

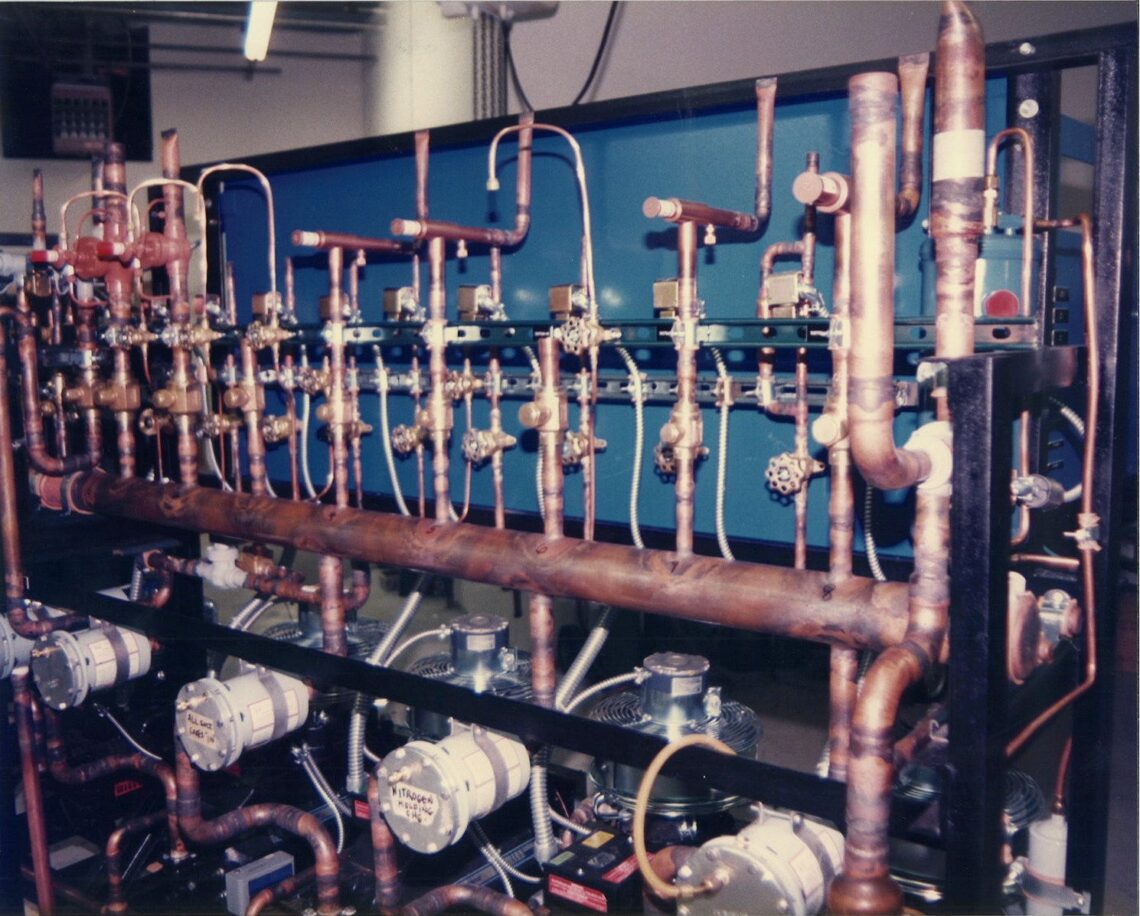

Oil Management Systems: Consistent Performance

Thermal Stability Solutions

Case Construction: Practical and Durable

Display Freezers: Performance Meets Presentation

Refrigerant Monitoring: Real-Time Insights

Subcooling Enhancements: Targeted Efficiency

Door Systems: Smooth Operation, Smart Design

Frameless Case Design: Clean and Functional

Airflow Optimization: Precision Cooling from Every Angle

Innovation in Action

At Zero Zone, innovation is guided by practical outcomes. As explored in the blog Boost Your Bottom Line with a Top Coil Merchandiser, design choices like top coil configurations can influence energy efficiency and product visibility. Similarly, Refrigerated Display Cases Are Smarter Than You Think highlights how modern case technologies support smarter operations, while Modernizing Your Refrigeration System and Industrial & Commercial Refrigeration System Cooling examine how updated systems can align with evolving performance and sustainability goals. These examples reflect how engineering decisions are grounded in real-world application—helping customers meet operational demands with greater confidence.

Zero Zone has the Answers to Your Challenge

Every Zero Zone product is engineered to solve real-world challenges, from reducing energy consumption to extending equipment life. Whether it’s a refrigerated display case, an industrial or commercial refrigeration system, or a custom-built solution, performance and practicality are always at the core.

As sustainability, efficiency, and smart technology become more critical than ever, Zero Zone continues to lead the way—delivering refrigeration solutions that make a measurable difference for our customers and the planet.

Looking ahead, we remain committed to helping our partners meet evolving demands with systems that are built to last and designed to perform.

If you’re ready to take the next step toward smarter refrigeration, we invite you to explore our product lineup or connect with our team to find the right solution for your operation.