CO₂ refrigeration systems are becoming the go-to modern, eco-friendly solution because environmental regulations are tightening, and as a result, energy efficiency is taking priority in commercial and industrial refrigeration operations. However, CO₂ refrigerant systems aren’t just a drop-in replacement for traditional refrigerants. Instead, they come with a unique set of considerations that ultimately impact performance, reliability, and long-term ROI.

In this blog, we’ll break down the basics of CO₂ (carbon dioxide) refrigeration in clear, practical terms. Whether you’re upgrading equipment, building a new facility, or exploring sustainable refrigeration options, this guide will help you understand what makes CO₂ systems different—and how to maximize their potential in your operation.

Why Choose CO₂ as a Refrigerant?

CO₂, also known as refrigerant R-744, is gaining momentum in the refrigeration industry for good reason:

- Low Environmental Impact: CO₂ has a Global Warming Potential (GWP) of just 1. In contrast, traditional refrigerants like R-404A have a GWP over 3,900.

- High Energy Efficiency: In the right conditions, CO₂ systems can outperform conventional refrigeration systems, particularly in cooler climates.

- Regulatory Compliance: CO₂ systems future-proof your facility by aligning with evolving environmental and refrigerant phase-down regulations.

However, CO₂ is not without its challenges. Specifically, system design, pressure management, and climate adaptability require careful consideration.

Key Differences: How CO₂ Refrigeration Systems Operate

CO₂ refrigeration systems function differently than traditional systems, and understanding these differences is key for informed decision-making.

-

Higher Operating Pressures

- CO₂ operates at much higher pressures than other refrigerants. Although this might sound alarming, today’s systems are built with specialized components designed to handle these conditions safely and reliably. Proper engineering and installation are essential.

-

Two Modes of Operation: Subcritical and Transcritical

- Subcritical Mode: In cooler climates or during colder months, CO₂ behaves like traditional refrigerants—operating at manageable pressures with efficient heat exchange.

- Transcritical Mode: In warmer environments, CO₂ enters a supercritical state, where it no longer behaves as a typical liquid or gas. This mode requires more advanced system controls and heat rejection strategies to maintain efficiency.

-

Unique Thermodynamic Properties

- CO₂ has a triple point and critical point that impact system design. These characteristics influence how heat is removed and, furthermore, how pressure is managed across the system, particularly in variable climates.

- Triple Point: The temperature and pressure where CO₂ can exist as a solid, liquid, and gas.

- Critical Point: The temperature where CO₂ becomes a supercritical fluid.

As energy costs rise, regulations evolve, and consumer demand for environmentally friendly solutions increases, evaluating your current commercial or industrial refrigeration system for a potential upgrade increases in importance. When considering an upgrade, several factors – such as the current condition of your equipment, maintenance costs, energy efficiency, and refrigerant type must be evaluated. Each of these factors play a role in determining the cost effectiveness of an upgrade.

Now that we have crossed into 2025, the first restrictions of the American Innovation and Manufacturing (AIM) Act are now in effect. The AIM Act of 2020 allows the EPA to restrict the production, import, and use of hydrofluorocarbons (HFCs). HFC refrigerants have a high global warming potential (GWP) and are being phased down by 85% through 2035.

The Refrigerants allowed by the AIM Act are not direct substitutes for HFC refrigerants. Refrigeration systems require different components, piping and programming with each refrigerant. The performance of refrigeration systems is influenced by the external ambient temperatures.

Equipment installed before restrictions go into effect are allowed to maintain operation throughout their useful life. This includes service, parts, and refrigerant. However, the availability of each is dependent on the manufacturer.

Retrofitted equipment and new installations have their own regulations and definitions. Retrofitted equipment, replacing at least 75% or more of the evaporators and 100% of the compressor racks, condensers, and connected evaporator loads of an existing system, will need to follow the restrictions for a new installation. For more information on the AIM Act and state regulations, visit our Refrigerant Regulations webpage.

Refrigeration Upgrades: Enhancing Energy Efficiency and Reducing Costs

Refrigeration systems are among the most energy-intensive systems in operation. Upgrading them can significantly increase their energy efficiency and reduce operational costs. Refrigeration Upgrades are essential for businesses looking to optimize their energy consumption and improve their bottom line.

Factors to Consider Before Upgrading

Refrigerated and Frozen Foods published an insightful article by John Collins, the Zero Zone Director of Industrial Sales

This article explores several factors that need to be considered before upgrading your industrial or commercial refrigeration system. These factors include:

- Energy Efficiency: Upgrading refrigeration systems can lead to substantial improvements in energy efficiency. Modern systems are designed to consume less power while maintaining optimal performance.

- Operational Costs: By enhancing energy efficiency, businesses can reduce their operational costs. Lower energy consumption translates to lower utility bills and overall cost savings.

- System Reliability: Newer refrigeration systems are built with advanced technology that ensures higher reliability and fewer breakdowns. This reduces maintenance costs and downtime.

- Environmental Impact: Upgraded systems often use eco-friendly refrigerants and technologies that minimize environmental impact. This aligns with sustainability goals and regulatory requirements.

Benefits of Refrigeration Upgrades

Investing in refrigeration upgrades offers numerous benefits:

- Improved Performance: Upgraded systems provide better cooling performance, ensuring that products are stored at the optimal temperature.

- Enhanced Control: Modern refrigeration systems come with advanced control features that allow precise temperature management and monitoring.

- Long-Term Savings: Although the initial investment may be significant, the long-term savings in energy costs and maintenance make it a worthwhile investment.

Real-World Example

John Collins discusses the impact of refrigeration upgrades in his article. He highlights how businesses have successfully reduced their energy consumption and operational costs by implementing modern refrigeration solutions. These upgrades not only improve efficiency but also contribute to a more sustainable operation.

Learn More

To delve deeper into the factors and benefits of refrigeration upgrades, read the full article by John Collins on Refrigerated and Frozen Foods

This comprehensive guide provides valuable insights into how refrigeration upgrades can transform your business.

To learn more about what Refrigeration System is right for your application, visit our systems page.

AIM Act Refrigerants: Driving Sustainable Business Practices

AIM Act Refrigerants are rapidly gaining priority as rising energy costs, evolving regulations, and increasing consumer demand for environmentally friendly solutions drive change. Consequently, sustainable business practices have become essential. In the refrigeration industry, the choice of refrigerant directly affects both energy costs and regulatory compliance. Therefore, this blog will explore the advantages and disadvantages of low-global warming potential (GWP) refrigerants, including Natural and Hydrofluoroolefin (HFO) options.

Zero Zone Reliability in Addressing Water Scarcity

In 2002, a severe drought agonized 33% of the contiguous United States. Crops and pastures suffered, wells ran dry, and reservoirs drained. In Colorado, over 3 million people lost their water security. Consequently, authorities implemented water restrictions. Residents limited outdoor lawn watering, which accounted for half of annual residential water use, to once a week and scheduled it by address numbers. Additionally, residents could not fill swimming pools during one of the warmest summers on record.

Planning for Future Droughts

After the drought broke, planning for the next one became a priority. An expansion project began on Colorado’s Gross Reservoir Dam, located in Boulder County, to prevent future water scarcity. The project aims to raise the dam by 131 feet, totaling 471 feet, to increase the reservoir’s capacity by 25 billion gallons of water. After the expansion, the dam will be three times its current size and the tallest concrete dam in Colorado.

Zero Zone’s Role in the Project

Although this project presents many challenges, one in particular caught the attention of Zero Zone: the heat concrete produces as it cures. Zero Zone reliability ensures that the project addresses this issue effectively, contributing to the overall success of the dam’s expansion and the prevention of future water scarcity.

A walk-in cooler turns into an oasis during the summer months. While this may bring you relief, it adds stress to your industrial or commercial refrigeration system. The efficiency of any refrigeration system drops as the ambient temperature increases. Pressure within the system also increases, putting strain on the entire system. For areas with warmer climates, this happens for a longer period of time during the year. There are many ways to mitigate stress and heat in your system, but which one works best for your application?

Industrial Refrigeration Solutions

Industrial Refrigeration Solutions differ significantly from retail refrigeration. For starters, they operate at different stages in the Cold Chain, which is a temperature-controlled supply chain for perishable goods. This supply chain begins with storage, processing, or both. Next, it moves to transportation, and finally arrives at the distribution stage.

Retail Refrigeration

Retail refrigeration exists within the distribution step. Think of places that need refrigeration and have a checkout counter. These systems are designed to keep products cool and fresh for consumers at the point of sale.

Industrial Refrigeration

In contrast, industrial refrigeration operates before the retail level. These systems are crucial for maintaining the quality and safety of products during storage and processing, ensuring that they remain fresh throughout transportation and up until they reach the retail stage.

Common Applications

Before we delve into the specifics of industrial refrigeration, let’s explore some common applications where Zero Zone systems have been used. These applications highlight the versatility and effectiveness of industrial refrigeration solutions in various settings.

What is the AIM Act?

The American Innovation and Manufacturing Act (AIM Act) was passed in 2020 by bipartisan support in the U.S Congress as the United States joined the global movement to reduce human impact on climate change. The AIM Act directs the U.S. Environmental Protection Agency (EPA) to oversee the phasedown of HFC refrigerant production and consumption in an effort to transition to alternative refrigerants. The AIM Act includes a phasedown schedule that began in 2022 and continues to 2036.

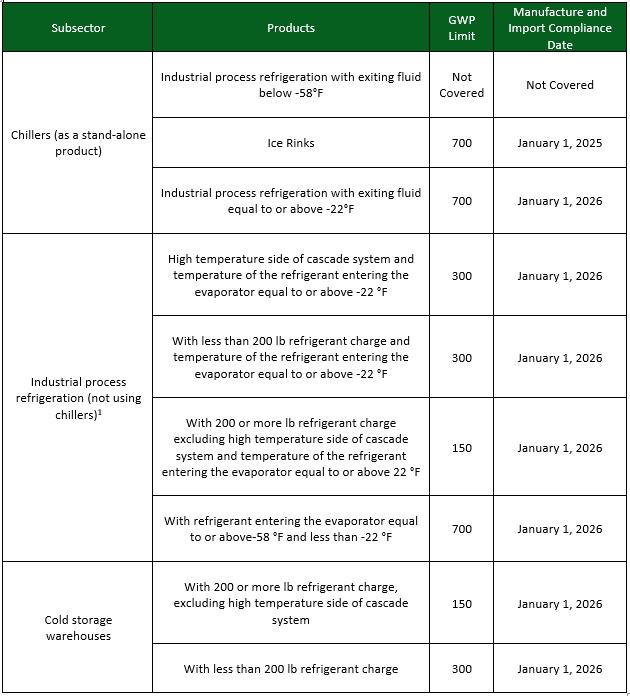

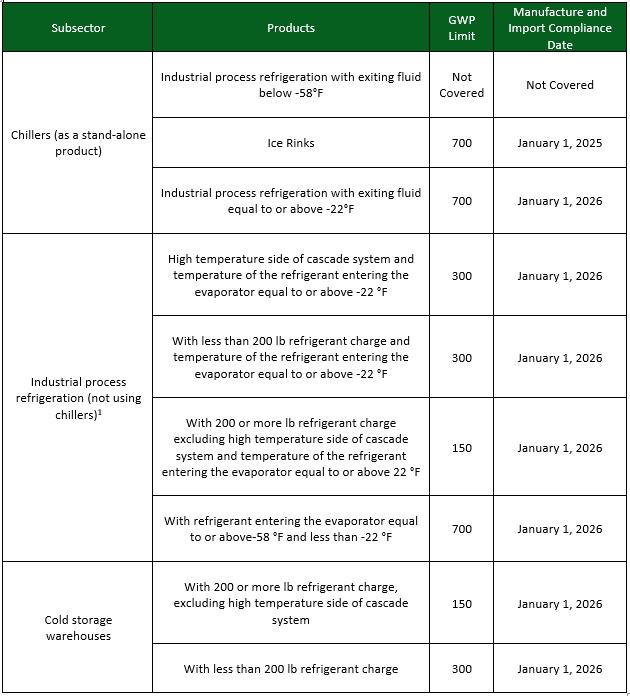

The new rule prohibits the manufacture and import of self-contained products that use hydrofluorocarbons (HFCs). The rule also prohibits the sale, distribution, and export of products three years after the manufacture and import restriction. Finally, it prohibits the installation of new refrigeration air conditioning and heat pump (RACHP) systems that contain HFCs. The compliance dates of these new rules vary based on sector and subsector.

Who does the AIM Act refer to?

The final rule states, “Entities that manufacture, import, export, sell, distribute, or install systems or products that use HFCs in refrigerants and air-conditioning equipment systems, heat pumps, foams, and aerosols may be affected by this new rule. Restrictions apply to original equipment manufacturers, product distributors, retailers, and companies that direct the installation of new RACHP systems.”

Important definitions

The final rule makes a distinction between products and systems. Certain products and the installation of certain systems have different restrictions.

A product is functional upon leaving a factory. Examples of products include self-contained refrigerators and self-contained ice machines. The EPA is restricting the sale, distribution and export of products containing higher-GWP HFCs three years after the manufacture and import restriction dates.

A system is assembled and charged in the field using multiple components. An example of a system is a supermarket refrigeration system that include a centralized compressor room. Components include equipment such as compressors, condensers, and display cabinets. There is not a restriction on the manufacture, import, sale, distribution, or export of components that are used to repair existing systems.

When will the phasedown start?

Industrial Phasedown

Retail Phasedown

Notes:

Notes:

- Industrial Process Refrigeration (IPR) systems are used to cool process streams at a specific location in manufacturing and other industrial processes (e.g., chemical, pharmaceutical, petrochemical, and manufacturing industries).

- Refers to the Zero Zone Hybrid™ display cases and rack condensing units (Edge XT).

- Refers to Zero Zone’s Highlight®, Crystal®, and Reveal® display cases and their associated systems.

Why was the AIM Act proposed and passed?

The AIM Act addresses petitions from industry, environmental organizations, and state governments to restrict the use of HFCs. The EPA has estimated the potential benefits of this rule will provide savings to American consumers and industry through energy efficiency and lower-cost refrigerants. The EPA stated that this rule will also result in greenhouse gas emissions reduction benefits.

- EPA estimations:

- Emission reduction of 876 million metric tons of carbon dioxide equivalent through 2050.

- $50.4 billion in climate change mitigation benefits

- $4.5 billion in cost savings to consumers and businesses driven by the lower cost of HFC substitutes and increased energy efficiency of lower-GWP refrigerants

For our customers

This rule does not restrict Zero Zone customers from using their existing refrigeration systems. The EPA has allowed an existing system to continue its operation to the end of its useful life. The systems may be serviced and repaired throughout their use, including replacing components. Components needed for repair are allowed to continue being manufactured.

For new installations, the equipment needs to be charged before the compliance dates. The following actions are considered a new installation:

- Assembling a system for the first time from used or new components;

- Increasing the cooling capacity, in BTU per hour, of an existing system; or

- Replacing 75 percent or more of evaporators (by number) and 100 percent of the compressor racks, condensers, and connected evaporator loads of an existing system.

Into the Future: Refrigerant Management

Although a system can be serviced until the end of its useful life, the refrigerants used to recharge it will become scarce as production slows. The costs of synthetic refrigerants are expected to rise. The EPA is currently working on a standard for refrigerant reclamation and requirements for reclaimed HFC refrigerants. They are proposing that as of January 1, 2028, reclaimed refrigerant must be used when servicing and/or repairing refrigerant-containing equipment. This includes supermarket systems and stand-alone retail food refrigeration.

If you have questions about these regulations, please contact Zero Zone and ask to speak to our Director of Regulatory Compliance & Refrigeration Technology, Bruce Hierlmeier.

How can Zero Zone Help?

At Zero Zone, we’ve always been green. Zero Zone offers sustainable refrigeration solutions with Genesys™ Natural Refrigeration Solutions. If you want to learn about our offerings and plans for these new regulations, contact our sales team or visit Zero Zone’s Genesys™ Natural Refrigeration Solutions webpage.

View the infographics for our Retail and Industrial customers for a summary of important facts and dates.

What changed?

The Environmental Protection Agency (EPA) finalized the phasedown schedule (above) for hydrofluorocarbons (HFCs), which is mandated by the American Innovation and Manufacturing Act (AIM Act). There were no changes between the proposal and the final rule. The schedule still calls for a segmented reduction in HFCs produced and consumed, ending in an 85% reduction by 2036.

The finalized rule includes an allocation and trading program, which determines the amount of refrigerant that may be produced and consumed. There were no changes between the proposal and the final rule.

Who is impacted by the AIM Act?

- Refrigerant Producers: Companies that produce, import, export, destroy, reclaim, or recycle HFCs are issued allowances by the EPA on October 1 of each year. These allowances are relative to the phasedown schedule.

- End Users: Companies that use refrigeration equipment—such as retailers, cold storage warehouses, and industrial process facilities—will feel an indirect impact because HFC refrigerant will be less common and more expensive.

We know from the recent phaseout of R-22 that this phasedown will cause refrigerant prices to rise. HFC refrigerants that are manufactured will primarily be used to service leaks in existing systems, plus HFC refrigerants are shared with other industries, such as air conditioning and foaming processing. This could impact cost and availability of refrigerants to retailers and industrial end users, meaning that budgets for repairs will need to increase.

What should retailers and other end users do?

To counteract this, Zero Zone recommends that future orders for refrigeration equipment should be switched to alternative refrigerants sooner than later, such as natural refrigerants and low-GWP HFO-based refrigerants. This will make service costs better in the long run. Plus, it will prepare end users for upcoming EPA rules that will further regulate refrigerants.

What other rules are coming?

The refrigeration industry awaits three more final EPA rules.

1) The EPA proposed a rule that will establish limits by 1/1/2025 on the global warming potential (GWP) of refrigerants. This rule must be finalized in October 2023. Below are the current GWP restrictions proposed.

These GWP limits will end the use refrigerants such as R-404A (GWP of 3943), R-407A (GWP of 1923), R-410A (GWP of 1924), R-448A (GWP of 1273), R-449A (GWP of 1282), and R-507 (GWP of 3985) in new equipment. Going forward, refrigeration equipment will need to use natural refrigerants, such as CO2 (GWP of 1), ammonia (GWP of 0), and HFO-based refrigerants with GWP less than the limits.

2) The refrigeration industry also awaits the release of EPA Rule 26, which will allow for the use of A2L refrigerants in commercial and industrial applications. “A2L” refers to an ASHRAE classification of refrigerants that are mildly flammable. Rule 26 would also increase the allowable R-290 (propane) charges for self-contained equipment.

3) The EPA will be updating Section 608 of the EPA Clean Air Act (CAA), which regulates handling, recovery, reclamation, and recycling of refrigerants. They are updating the rule for how service technicians can handle refrigerants and how refrigerant use is reported by store owners.

Further Reading

For more information about upcoming EPA regulations: “The National Plan for Refrigerant Regulations.”

For more information about current state regulations: “The State of Refrigerant Regulations.”

If you have questions about these regulations, please contact Zero Zone and ask to speak to our Director of Regulatory Compliance & Refrigeration Technology. If you want to learn about our offerings and plan for these regulations, contact our sales team.

Notes:

Notes: