The Highlight Merchandiser® is a durable display case that exudes classic charm. This workhorse not only offers a generous packout but also provides a spectacular, full view of your product. Whether you need to protect frozen food, ice cream, beverages, dairy, deli items, meat, ice, or produce, the Highlight Merchandiser® rises to the occasion. Moreover, its robust construction ensures longevity, while its elegant design enhances the visual appeal of any retail space. Thus, the Highlight Merchandiser® seamlessly combines functionality and aesthetics, making it an ideal choice for showcasing a wide variety of products.

Zero Zone reliability has built a trust with customers across North America. This trust grew from our small town in Wisconsin by selling to local retailers, such as Webster’s Marketplace. When Webster’s Marketplace expands, they choose Zero Zone for their refrigerated display cases. DuWayne Wichman, one of the store directors, has said in an interview, “I can’t say enough good things about [Zero Zone refrigerated display cases].” Inside Webster’s Marketplace, you’ll find Zero Zone display cases in operation from 1984, 2005, 2015, 2017, and 2024.

The Reveal Merchandiser®

The Reveal Merchandiser® aligns with the diversity of your product by offering a variety of features. Specifically, it provides options for beverages, dairy, deli, meat, and produce. Additionally, the multitude of lighting, shelf, and accessory choices empowers you to take control of creative merchandising.

The Lineup

Before we can accessorize a display case, we have to know what we are working with. Zero Zone has four models for the Reveal Merchandiser® display case.

The Zero Zone Crystal Merchandiser® is more than a display case to keep your products cold, it is used to show off your product’s best features. Crystal Merchandiser® applications include floral displays, produce, dairy, deli, wine, beverages, ice cream, and frozen foods. The versatility of the Crystal Merchandiser® applications does not end with what can be displayed, but how its contents can be displayed.

What is a Small Format Store?

A Small format store typically measures less than 25,000 ft² and requires less than 30 tons of refrigeration capacity. These stores often include convenience stores, small grocery stores, and pharmacies. Due to their size, small format stores lack the space or lease agreements needed to install the large rack units favored by large-format retailers. Additionally, organizing small format stores to fit display cases presents another complication.

Why CO2?

Carbon dioxide (CO2) as a refrigerant offers several advantages:

- It significantly reduces the environmental impact and plays a crucial role in combating climate change.

- CO2 is the gold standard for ozone depletion potential (ODP) at 0.

- It has a global warming potential (GWP) of 1.

Many countries, including the US, are phasing out high-GWP synthetic refrigerants and enforcing stricter environmental regulations. Embracing CO2 ensures compliance with these evolving regulations, avoiding penalties and legal complications.

CO2 is nonflammable, nontoxic, and a low-cost refrigerant. The recent advent of high-pressure, iron-impregnated copper has allowed the transition from traditionally stainless-steel piping to familiar brazed copper piping, further improving value and simplifying repairs.

Is CO2 Right for Your Small Format Store?

CO2 is also a low-cost refrigerant. Most synthetic refrigerants can cost upwards of $20 per lb, whereas the current price of CO2 is around $3 per lb. CO2 systems require smaller copper pipes than other refrigeration systems, which decreases installation costs. Additionally, CO2 systems have excellent energy efficiency, minimizing operational costs. Its high density and low viscosity increase coil efficiency, allow for smaller line sizes, and take advantage of smaller compressors.

Although everyone with a CO2 system can enjoy its benefits, small format stores can go a step further. Since small format refrigeration systems require less refrigerant, they do not need heat removal through air conditioning. This means the heat reclaim can be used for space heating, dehumidification, commercial kitchens, and restrooms.

Zero Zone understands that one size does not fit all. Our Genesys™ Natural Refrigeration Systems can be tailored for small format stores with the following products.

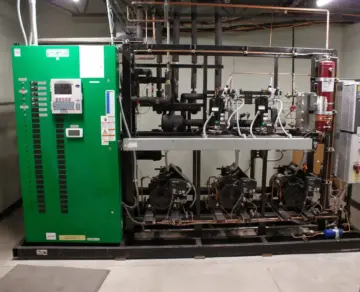

Indoor Parallel Systems

Outdoor Parallel Systems

Distributed Refrigeration Systems

Real World Examples

Here are some case studies of using Zero Zone’s CO2 Genesys™ Natural Refrigeration Systems in small format stores:

Small grocery store in Stapleton, CO

- Zero Zone completed this project using an indoor parallel system that can operate on a mezzanine in a mechanical room in a 5B climate zone. It has a remote adiabatic gas cooler, negating the need for air conditioning. The design pressure is 120 bar on the high side and 45 bar on the low side.

Small format store in Islandia, NY

- This store is located in a 4A climate zone and home to one of Zero Zone’s outdoor parallel roof-mounted rack systems. This system has a remote air-cooled gas cooler and a design pressure of 120 bar high side and 90 bar low side.

Convenience Store in Dayton, MN

- Zero Zone also has an outdoor parallel system mounted on the roof in a 6A climate zone. This system measures 120 bar on its high side and 45 bar on its low side. This location also uses the heat reclaim for heating the backroom air coil and water.

A common myth surrounding CO2 as a refrigerant is that it can only be used in certain climates. This is true only for certain types of CO2 systems. Transcritical CO2 systems can only be used in cooler climate zones. Subcritical CO2 systems can be used in any climate zone. At Zero Zone, we have a solution for natural refrigerants in any climate.

Are You Ready for Zero Zone’s Genesys™ CO2 System?

To start a project or learn more about how Zero Zone can help, contact one of our sales representatives.

What is the AIM Act?

The American Innovation and Manufacturing Act (AIM Act) was passed in 2020 by bipartisan support in the U.S Congress as the United States joined the global movement to reduce human impact on climate change. The AIM Act directs the U.S. Environmental Protection Agency (EPA) to oversee the phasedown of HFC refrigerant production and consumption in an effort to transition to alternative refrigerants. The AIM Act includes a phasedown schedule that began in 2022 and continues to 2036.

The new rule prohibits the manufacture and import of self-contained products that use hydrofluorocarbons (HFCs). The rule also prohibits the sale, distribution, and export of products three years after the manufacture and import restriction. Finally, it prohibits the installation of new refrigeration air conditioning and heat pump (RACHP) systems that contain HFCs. The compliance dates of these new rules vary based on sector and subsector.

Who does the AIM Act refer to?

The final rule states, “Entities that manufacture, import, export, sell, distribute, or install systems or products that use HFCs in refrigerants and air-conditioning equipment systems, heat pumps, foams, and aerosols may be affected by this new rule. Restrictions apply to original equipment manufacturers, product distributors, retailers, and companies that direct the installation of new RACHP systems.”

Important definitions

The final rule makes a distinction between products and systems. Certain products and the installation of certain systems have different restrictions.

A product is functional upon leaving a factory. Examples of products include self-contained refrigerators and self-contained ice machines. The EPA is restricting the sale, distribution and export of products containing higher-GWP HFCs three years after the manufacture and import restriction dates.

A system is assembled and charged in the field using multiple components. An example of a system is a supermarket refrigeration system that include a centralized compressor room. Components include equipment such as compressors, condensers, and display cabinets. There is not a restriction on the manufacture, import, sale, distribution, or export of components that are used to repair existing systems.

When will the phasedown start?

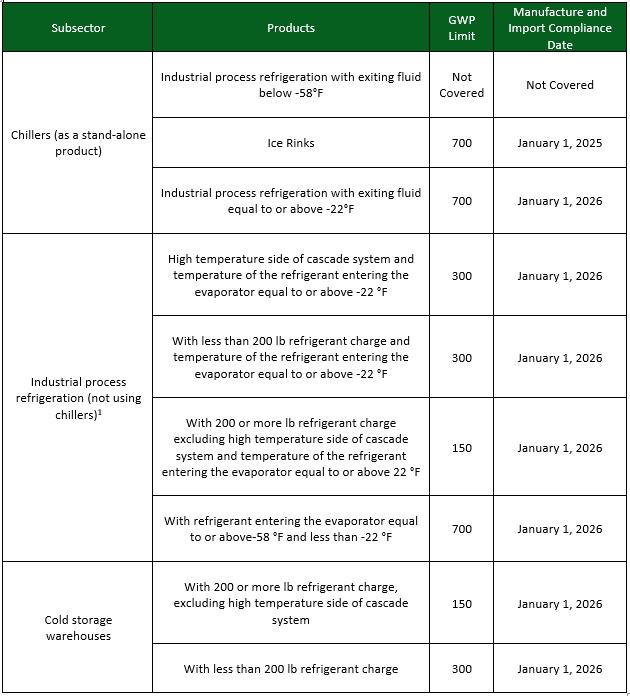

Industrial Phasedown

Retail Phasedown

Notes:

Notes:

- Industrial Process Refrigeration (IPR) systems are used to cool process streams at a specific location in manufacturing and other industrial processes (e.g., chemical, pharmaceutical, petrochemical, and manufacturing industries).

- Refers to the Zero Zone Hybrid™ display cases and rack condensing units (Edge XT).

- Refers to Zero Zone’s Highlight®, Crystal®, and Reveal® display cases and their associated systems.

Why was the AIM Act proposed and passed?

The AIM Act addresses petitions from industry, environmental organizations, and state governments to restrict the use of HFCs. The EPA has estimated the potential benefits of this rule will provide savings to American consumers and industry through energy efficiency and lower-cost refrigerants. The EPA stated that this rule will also result in greenhouse gas emissions reduction benefits.

- EPA estimations:

- Emission reduction of 876 million metric tons of carbon dioxide equivalent through 2050.

- $50.4 billion in climate change mitigation benefits

- $4.5 billion in cost savings to consumers and businesses driven by the lower cost of HFC substitutes and increased energy efficiency of lower-GWP refrigerants

For our customers

This rule does not restrict Zero Zone customers from using their existing refrigeration systems. The EPA has allowed an existing system to continue its operation to the end of its useful life. The systems may be serviced and repaired throughout their use, including replacing components. Components needed for repair are allowed to continue being manufactured.

For new installations, the equipment needs to be charged before the compliance dates. The following actions are considered a new installation:

- Assembling a system for the first time from used or new components;

- Increasing the cooling capacity, in BTU per hour, of an existing system; or

- Replacing 75 percent or more of evaporators (by number) and 100 percent of the compressor racks, condensers, and connected evaporator loads of an existing system.

Into the Future: Refrigerant Management

Although a system can be serviced until the end of its useful life, the refrigerants used to recharge it will become scarce as production slows. The costs of synthetic refrigerants are expected to rise. The EPA is currently working on a standard for refrigerant reclamation and requirements for reclaimed HFC refrigerants. They are proposing that as of January 1, 2028, reclaimed refrigerant must be used when servicing and/or repairing refrigerant-containing equipment. This includes supermarket systems and stand-alone retail food refrigeration.

If you have questions about these regulations, please contact Zero Zone and ask to speak to our Director of Regulatory Compliance & Refrigeration Technology, Bruce Hierlmeier.

How can Zero Zone Help?

At Zero Zone, we’ve always been green. Zero Zone offers sustainable refrigeration solutions with Genesys™ Natural Refrigeration Solutions. If you want to learn about our offerings and plans for these new regulations, contact our sales team or visit Zero Zone’s Genesys™ Natural Refrigeration Solutions webpage.

View the infographics for our Retail and Industrial customers for a summary of important facts and dates.

What changed?

The Environmental Protection Agency (EPA) finalized the phasedown schedule (above) for hydrofluorocarbons (HFCs), which is mandated by the American Innovation and Manufacturing Act (AIM Act). There were no changes between the proposal and the final rule. The schedule still calls for a segmented reduction in HFCs produced and consumed, ending in an 85% reduction by 2036.

The finalized rule includes an allocation and trading program, which determines the amount of refrigerant that may be produced and consumed. There were no changes between the proposal and the final rule.

Who is impacted by the AIM Act?

- Refrigerant Producers: Companies that produce, import, export, destroy, reclaim, or recycle HFCs are issued allowances by the EPA on October 1 of each year. These allowances are relative to the phasedown schedule.

- End Users: Companies that use refrigeration equipment—such as retailers, cold storage warehouses, and industrial process facilities—will feel an indirect impact because HFC refrigerant will be less common and more expensive.

We know from the recent phaseout of R-22 that this phasedown will cause refrigerant prices to rise. HFC refrigerants that are manufactured will primarily be used to service leaks in existing systems, plus HFC refrigerants are shared with other industries, such as air conditioning and foaming processing. This could impact cost and availability of refrigerants to retailers and industrial end users, meaning that budgets for repairs will need to increase.

What should retailers and other end users do?

To counteract this, Zero Zone recommends that future orders for refrigeration equipment should be switched to alternative refrigerants sooner than later, such as natural refrigerants and low-GWP HFO-based refrigerants. This will make service costs better in the long run. Plus, it will prepare end users for upcoming EPA rules that will further regulate refrigerants.

What other rules are coming?

The refrigeration industry awaits three more final EPA rules.

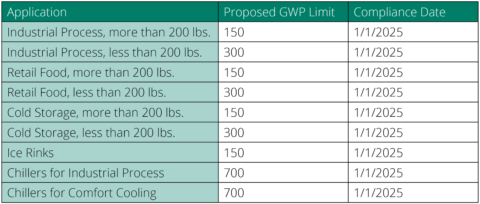

1) The EPA proposed a rule that will establish limits by 1/1/2025 on the global warming potential (GWP) of refrigerants. This rule must be finalized in October 2023. Below are the current GWP restrictions proposed.

These GWP limits will end the use refrigerants such as R-404A (GWP of 3943), R-407A (GWP of 1923), R-410A (GWP of 1924), R-448A (GWP of 1273), R-449A (GWP of 1282), and R-507 (GWP of 3985) in new equipment. Going forward, refrigeration equipment will need to use natural refrigerants, such as CO2 (GWP of 1), ammonia (GWP of 0), and HFO-based refrigerants with GWP less than the limits.

2) The refrigeration industry also awaits the release of EPA Rule 26, which will allow for the use of A2L refrigerants in commercial and industrial applications. “A2L” refers to an ASHRAE classification of refrigerants that are mildly flammable. Rule 26 would also increase the allowable R-290 (propane) charges for self-contained equipment.

3) The EPA will be updating Section 608 of the EPA Clean Air Act (CAA), which regulates handling, recovery, reclamation, and recycling of refrigerants. They are updating the rule for how service technicians can handle refrigerants and how refrigerant use is reported by store owners.

Further Reading

For more information about upcoming EPA regulations: “The National Plan for Refrigerant Regulations.”

For more information about current state regulations: “The State of Refrigerant Regulations.”

If you have questions about these regulations, please contact Zero Zone and ask to speak to our Director of Regulatory Compliance & Refrigeration Technology. If you want to learn about our offerings and plan for these regulations, contact our sales team.

At Zero Zone, the gold standard is a crystal: a Crystal Merchandiser®. These reach-in display cases have served retailers across every application: beverage, dairy, deli, meat, produce, and frozen food. To understand why, let’s look at 5 reasons that retailers love the Crystal Merchandiser®.

#1: Excellent Energy Efficiency

Up to 84% less energy than open multi-decks

Up to 45% less energy than other reach-in coolers

We know what matters most of all, and that is profit and cost. The Crystal Merchandiser® is the clear choice for maximizing profit while minimizing operating cost. These cases were engineered for excellent energy efficiency, especially against open multi-deck cases (up to 84% less energy) and even against other reach-in coolers (up to 45% less energy).

A retailer’s vice president of facilities and equipment said, “The energy savings are what really make you stop and say, ‘I need to take a serious look at this’. Then you start getting into things that become more apparent once you have the cases in—the comfort in the aisle, how great the product labels appear from the LED lighting—all of those subsequent advantages.”

#2: 74″ Tall CoolView® Doors

Not only do Zero Zone cases have excellent energy efficiency, but they are energy efficient while also having some of the largest doors in the industry. These 74″ tall doors open up the Crystal Merchandiser® to shoppers, making it easy for them to see products and make their selection.

Our 30″ wide CoolView® Illusion® doors for our low-temperature cases are known for glass that goes all the way to the edge of the door, giving the impression that the case is open even when the door is closed. The effect is most dramatic for a lineup of cases where the aisle will look like a wall of enticing product. Shoppers may be under the illusion that the door is not even there.

Crystal Merchandiser® Low Temp RVLC30 with CoolView® Illusion® Doors

The medium-temperature cases use CoolView® Ultra™ doors, which are notable for their broad display and slender frames. These are available as either 24″ wide French-swing doors or as 30″ wide single-swing doors. This lets retailers pick the right door to fit their merchandising strategy and store planogram.

#3: More Facings & More Packout

With taller doors comes increased product facings: up to 35% more facings than other display cases. In addition, the Crystal Merchandiser® also offers more merchandising space with 6 full shelves, which means up to 25% more packout. “We are able to get an entire case of 6-packs out as well as 3 12-packs on each shelf,” a liquor store manager noted. “You might think that with 6 shelves instead of 5, it might be more difficult for the consumer to pull product off of the shelving, but it has actually been easier.”

For even more space, take a look at the Zero Zone Deep cases, which allows you to fit 4 30-packs of 12 oz. cans in the bottom basket.

Crystal Merchandiser® Medium Temp RVMC30D Deep Case

Extra space can be valuable in any department in a store. Another store manager said, “In the yogurt section, with the old open cases that weren’t self-feeding, you would have to restock after you sold 6 units—or pull it all forward. But in this situation, you fill it once, you go back in mid-day and refill it. I mean, the labor savings is astronomical—about an hour and a half a day. That’s one of the ways we’ve been able to cut some inefficiencies.”

#4: More Efficient Use of Floor Space

Part of the genius of the Crystal Merchandiser® is that in addition to offering more facings and packout, the case actually uses less floor space within stores. The Crystal Merchandiser® is only 39 1/2″ from the back of the case to the front of the door handle. It is up to 7″ narrower than multi-deck cases. This allows retailers to use that space elsewhere or to simply have wider aisles, which shoppers appreciate.

#5: Reduced Shrink & Increased Shelf Life

The Crystal Merchandiser® also helps stores by reducing product shrink and increasing shelf life, which is especially pertinent to meat departments and produce departments.

In the words of a meat department manager, “Are the products holding up better? Absolutely! There’s no question it’s enhanced the shelf-life of the products.” The manager also reported that the meat held its vibrant, fresh color longer. A meat cutter told us, “It actually preserves the meat longer, gives it more life. It’s better for the customer; they get a fresher product. It’s better for us, as a company; we save more money, and we sell more, too.”

This benefit carries over to the produce department. Anything you put in the Crystal Merchandiser® stays fresh and beautiful longer. Spoilage is down, and shoppers take home produce that is fresher. As a produce department manager told us, “Since we began using the Crystal Merchandiser®, our shrink on bagged salad and cut fruit has been reduced by as much as 50%. The consistent temperature is the key.”

Are You Ready?

Have you fallen in love with the Crystal Merchandiser® too? Now is the time to contact the Zero Zone sales team to choose the Crystal Merchandiser® for your next store.

The Genesis of Refrigeration

Genesys™ Natural Refrigeration Solutions takes us back to the beginning. Carbon dioxide (CO2) and ammonia (NH3) have always been in our environment, and they have also always been part of the story of refrigeration. Both served as refrigerants in the 1800s. However, synthetic refrigerants emerged, causing their use to decline. Now, the AIM Act and upcoming EPA rules will propel the industry away from environment-damaging HFC refrigerants and toward low global warming potential (GWP) options. Consequently, natural refrigerants are once again a rising option for refrigeration.

Introducing Genesys™ Natural Refrigeration Solutions

That is why Zero Zone presents Genesys™ Natural Refrigeration Solutions. It is time to return to the beginning—the genesis—of refrigeration with CO2 (R-744) and ammonia (R-717) systems. CO2 and ammonia are the gold standard for ozone depletion potential (ODP) and global warming potential (GWP). Neither depletes the ozone (0). CO2 has a GWP of 1, as it is used as the baseline for that scale, and ammonia has a GWP of 0. For performance, CO2 is known for its high cooling capacity, and ammonia has a reputation for excellent energy efficiency. Natural refrigerants are a future-proof solution that exceeds modern sustainability goals, allowing customers to make the best choice for themselves and for the environment. Natural refrigerants are the natural choice.

The Time to Act is Now

Upcoming EPA regulations will end the use of most HFC refrigerants by 2025. Therefore, today is the day to choose Genesys™ Natural Refrigeration Solutions for your next project. For more information about the Genesys™ CO2 systems, watch our video and learn more at our website.

The American Innovation and Manufacturing Act (AIM Act) directs the Environmental Protection Agency (EPA) to regulate the transition to alternative refrigerants. It phases down the production and consumption of HFC refrigerants. The EPA has published a proposed rule that will prohibit the manufacture of equipment containing HFCs by January 1, 2025. It will also prohibit the sale of those products by January 1, 2026.

Read more about the AIM Act in 2025 here.

Which states are affected by the AIM Act?

This rule would apply to the entire country, bringing alignment instead of state-by-state regulations. States can still issue their own, more stringent regulations. Some states, like California and New York, will still require attention.

Which refrigerants are affected?

This rule proposes to restrict the use of refrigerants by their global warming potential (GWP). Equipment using more than 200 lbs. of refrigerant will face a GWP limit of 150. Equipment using less than 200 lbs. of refrigerant will face a GWP limit of 300. Chiller systems will face a GWP limit of 700.

These GWP limits will end the use of refrigerants like R-404A (GWP of 3943), R-407A (GWP of 1923), R-410A (GWP of 1924), R-448A (GWP of 1273), R-449A (GWP of 1282), and R-507 (GWP of 3985) in new equipment. Refrigeration equipment will need to use natural refrigerants, such as CO₂ (GWP of 1) and ammonia (GWP of 0). HFO-based refrigerants will also be used since they have options below the proposed GWP limits.

When will the AIM Act ruling be finalized?

Currently, the proposed rule is available for comments until January 30, 2023. The rule will be finalized in October 2023. We do not expect the GWP limits to change. However, the implementation date might get pushed back to help manufacturers and end users complete existing projects. Industry leaders are asking for clarification about how the implementation dates are defined. They also seek clarification on how “new projects” will be defined compared to retrofit or remodel projects.

Further Reading

Zero Zone has a new paper, “The National Plan for Refrigerant Regulations,” which has more information about the upcoming EPA regulations, which states will still have regulations to follow, and solutions that Zero Zone offers.

To know where we have come from, Zero Zone has a paper, “The State of Refrigerant Regulations,” which covers state regulations that affected the United States from 2019 through 2024.

The proposed rule and a succinct fact sheet are available on the EPA website: https://www.epa.gov/climate-hfcs-reduction/technology-transitions.

If you have questions about these regulations, please contact Zero Zone and ask to speak to our Director of Regulatory Compliance & Refrigeration Technology. If you want to learn about our offerings and plan for these regulations, contact our sales team.

Notes:

Notes: