The Next Generation of Self-Contained Merchandisers

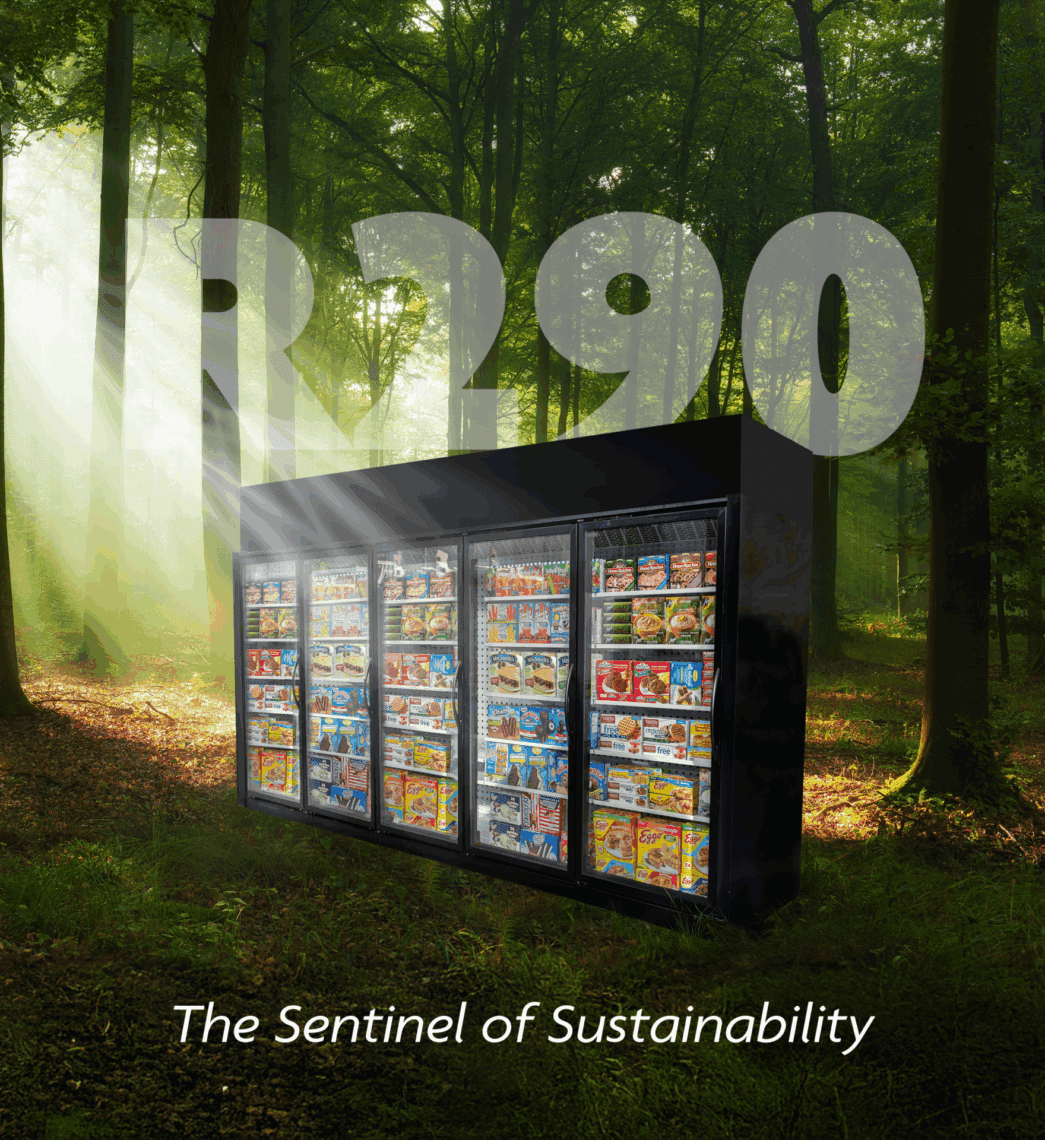

In an era where environmental responsibility meets retail innovation, the Guardian® Merchandiser stands as the sentinel of sustainability in retail refrigeration. Designed by Zero Zone, this self-contained refrigerated display case is more than just a product—it’s a statement of commitment to both performance and the planet. By using R-290 (Propane), these display cases are designed to meet current environmental standards and remain compliant well into the future.

Propane is a highly efficient refrigerant that delivers powerful cooling with minimal energy consumption. Its thermodynamic properties allow refrigeration systems to operate at lower pressures and with smaller compressor loads, making it perfect for self-contained refrigerated display cases.

The Guardian® Merchandiser is engineered for versatility and ease of use. With roof-mounted packaged refrigeration units (PRUs), retailers can enjoy plug-and-play simplicity that minimizes installation time and maximizes merchandising space. Available in 2 to 5-door configurations, the case supports low and medium temperature applications.

At Zero-Zone, our strategic priorities—organizational excellence, team development, and consistent communication—aren’t just guiding principles; they’re the foundation of how we operate and support our people. These values shape everything from daily interactions to long-term initiatives, creating a workplace where connection, collaboration, and pride in our work thrive. Whether you’re an intern just starting out or a long-term team member, you’re part of a culture that values growth, celebrates contributions, and builds community every step of the way.

The refrigeration industry is approaching a major transition. Under the American Innovation and Manufacturing (AIM) Act, the United States is phasing down the use of high-GWP refrigerants—most notably traditional HFCs. Starting January 1, 2026, these refrigerants will no longer be permitted in new commercial or industrial refrigeration systems. However, systems installed before this deadline can continue operating and be serviced throughout their useful life, provided repairs don’t result in a full system replacement.

The AIM Act, passed in 2020, directs the EPA to cut HFC production and consumption by 85% by 2036. This phasedown began in 2022 and is reinforced by the Technology Transition Rule, finalized in October 2023. This rule sets the maximum GWP limits for refrigerants in new systems. Each sector in the refrigeration industry has varying compliance dates. Understanding these compliance dates will help you make the right choice for the future.

As the refrigeration industry pivots toward environmentally conscious technologies, CO2 (R-744) systems are gaining traction for their low GWP and high efficiency. But with those advantages come a unique set of operational characteristics, and that means maintenance routines are a little different compared to traditional HFC/HFO systems.

Whether you’re already using CO2 systems or exploring a transition, understanding the nuances of preventative maintenance is essential to keep equipment running smoothly, safely and efficiently.

Why Preventative Maintenance Matters

All refrigeration systems benefit from preventative maintenance. The high operating pressures and sensitivity to moisture make consistent system checks a top priority.

Let’s break down the key maintenance tasks and what makes CO2 systems unique.

When it comes to refrigerated display cases, condensation is more than just an annoyance, it’s a barrier between your customers and your products. Fogged-up glass can mean missed sales opportunities and dripping water on the floor can create a slip hazard. This is why Zero Zone integrates anti-sweat technology into its refrigerated display. A hassle-free answer for retailers and store operators to keep their doors clear and clean while maintaining safe aisles.

In 1961, tucked into the rolling countryside of Pewaukee, Wisconsin, three refrigeration experts—George Johnson, Duke Wegner, and K. Hirata—converted a dairy barn into a workshop. An example in Midwest practicality. With a few tools, a lot of know-how, and a shared belief that refrigeration could be done better, they got to work. That barn became the birthplace of a company built on ingenuity—where resourcefulness, grit, and hands-on problem-solving weren’t just values; they were the business plan.

And it worked.

This month marks the 64th anniversary of Zero Zone. Since 1961, the company has focused on developing refrigeration systems that are efficient, reliable, and aligned with evolving industry needs. That focus continues today, with solutions designed to support energy savings, reduce maintenance, and maintain consistent product temperatures.

This blog highlights how Zero Zone’s technologies have contributed to commercial and industrial refrigeration—and how they continue to offer practical value.

As federal, state, and international bodies intensify efforts to phase down hydrofluorocarbons (HFCs), the commercial and industrial refrigeration sectors must adapt to a rapidly changing regulatory landscape. State and local regulations are allowed to have requirements that exceed federal EPA regulations. California, Washington, and New York have finalized comprehensive regulations, while adhering to the AIM Act, governing the use of high-GWP refrigerants, leak detection and repair, and system transition timelines. The standard GWP metric typically reflects a 100-year time horizon, referred to as GWP100, when evaluating the climate impact of refrigerants.

Below is an overview of these evolving requirements and how they impact your operations.

Top coil refrigerated display cases are known for their consistent refrigeration performance and flexible merchandising. These refrigerated display cases feature the evaporator coil at the top, promoting even airflow, enhanced product visibility, and maximum shelf life—all key advantages for store managers looking to improve product presentation and profitability.

In this blog, we will explore the advantages of top coil refrigerated display cases and how to use them to your advantage.

What is the Cold Chain

The cold chain is a vital part of modern logistics. It is a process to ensure that temperature-sensitive products, such as food and pharmaceuticals, remain safe, stable, and effective throughout their production, storage, and delivery. It involves a continuous sequence of temperature-controlled processes and specialized equipment designed to maintain product integrity from origin to end use.

The Importance of the Cold Chain

Multiple industries rely on proper procedures. In the food and beverage sector, the cold chain preserves freshness and nutritional value in perishable items such as dairy, meat, produce, and frozen goods. In healthcare, it safeguards the potency of vaccines, biologics, and temperature-sensitive medications. The chemical industry also relies on the cold chain to ensure quality control for sensitive materials that degrade with temperature fluctuations.

Key Components

A successful cold chain consists of four major stages:

- Production: Temperature-sensitive products must be properly handled immediately after harvest or manufacture. Maintaining the correct environment from the start helps preserve product safety and quality.

- Storage: Once produced, items are stored in refrigerated environments—ranging from cold rooms to large-scale refrigerated warehouses. These spaces can be equipped with temperature monitoring and backup systems to maintain consistency.

- Transportation: Specialized vehicles such as refrigerated trucks, containers, and air or sea freight systems ensure goods remain within specified temperature ranges throughout transit.

- Distribution: The final step delivers products to retailers, foodservice locations, pharmacies, and other establishments that serve end-users. Cold chain integrity must be upheld through last-mile delivery and in-store refrigeration systems.