Propane Refrigeration: The Rise, Fall and Return to this Natural Refrigerant

Propane is not a new refrigerant. It is a proven solution that has re-emerged as the industry evaluates efficiency, safety, and environmental impact together.

Early refrigeration systems relied on refrigerants that were effective but carried significant drawbacks. As technology and regulations evolved, so did refrigerant selection. Today, propane refrigeration represents a return to a refrigerant that meets modern performance requirements while aligning with current environmental standards.

A Brief History of Refrigeration

The fundamental principle of refrigeration, removing heat through the evaporation of a working fluid, was demonstrated in 1748 by William Cullen. Practical refrigeration systems followed in the 19th century, beginning with vapor-compression designs described by Oliver Evans and later patented and built by Jacob Perkins in 1834.

By the late 1800s, commercial refrigeration systems commonly used ammonia, carbon dioxide (CO2), and other, often volatile, refrigerants. While effective, each presented challenges related to toxicity, operating pressure, or system reliability.

Early Adoption of Propane Refrigerant

Shift to Synthetic Refrigerants

Re-Evaluating Refrigerant Choices

Advantages of Propane Refrigerant

No Temperature Glide

Propane is a single-component refrigerant. Phase change occurs at a consistent temperature and pressure, improving stability and performance predictability.

Energy Efficiency

Propane has a high latent heat of vaporization, allowing systems to achieve required cooling capacity with a smaller refrigerant charge.

This contributes to improved heat transfer, lower operating pressures and reduced compressor load.

Propane’s Environmental Impact

Propane has a GWP of less than 1. For reference, CO2 has a GWP of 1.

Propane is not subject to current HFC phase-down regulations and remains widely available.

Safety by Design

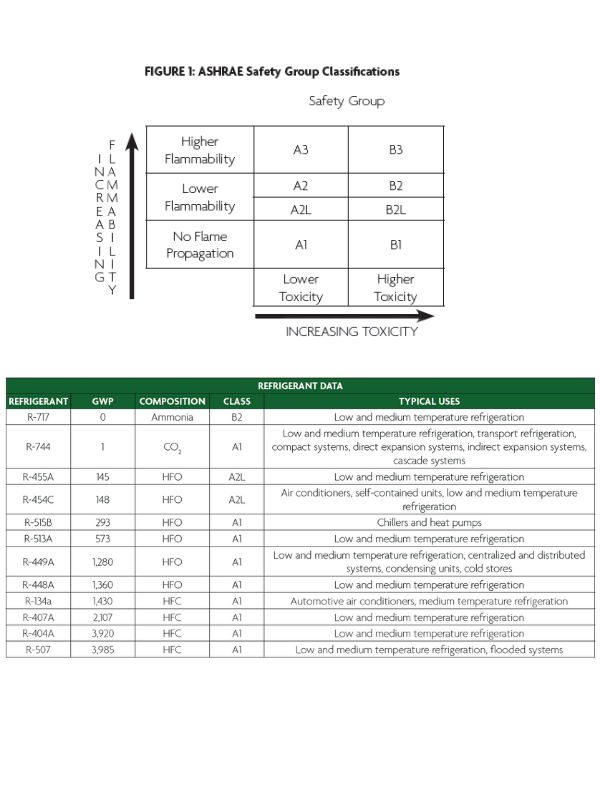

Propane is classified as an A3 refrigerant, meaning it is non-toxic and flammable. Safe application is achieved through controlled charge sizes, system architecture, and compliance with applicable safety standards.

The Guardian® Merchandiser: A Modern Self-Contained Propane Solution for Retail Refrigeration

Guardian® is our answer to what retailers need now: a compliance‑ready, energy‑efficient, and service‑friendly display case that brings grocery‑style merchandising to self‑contained refrigeration—powered by R‑290 (propane).

Why Guardian®

- Future‑proof refrigerant: R‑290 delivers ultra‑low GWP (<1) and zero ODP, aligning with AIM Act transitions and sustainability goals.

- Plug‑and‑play serviceability: Packaged Refrigeration Units (PRUs) are engineered for quick replacement and simplified maintenance—without field piping, charging, or brazing.

- Continuous lineups: Join cases to create a seamless, full‑size lineup with the merchandising capacity and aesthetics you expect from grocery‑style equipment.

- Lower total cost of ownership: Efficient heat transfer and smart case architecture help reduce energy use and minimize service complexity.

How it’s engineered

- Self‑contained Packaged Refrigeration Unit (PRU) design: Each PRU is intentionally kept below 150 g of propane, less than a standard beverage can, for A3 safety compliance—eliminating the need for leak‑mitigation devices at the PRU level.

- Optimized thermodynamics: High latent heat of vaporization and stable single‑component refrigerant behavior (no glide) support consistent product temperatures and predictable performance.

- Standards alignment: Designed to meet applicable DOE/NSF requirements and Zero Zone performance benchmarks.

Configurations

- Door counts: 2‑, 3‑, 4‑, and 5‑door options

- Temperatures: Medium‑temperature and low‑temperature models

- Charge strategy:

- MT PRU: 120 g per PRU (case totals scale by PRU count)

- LT PRU: 135 g per PRU (case totals scale by PRU count)

- PRU counts: 2‑door (1 PRU), 3‑/4‑door (2 PRUs), 5‑door (3 PRUs)

Built for retail realities

Whether you’re expanding a lineup, remodeling a department, or deploying natural refrigerants across locations, Guardian® delivers the merchandising capacity, compliance, and service simplicity that modern retail demands.

Refrigeration Expertise that Matters

Selecting a refrigerant involves more than regulatory compliance. Performance, reliability, safety and long-term viability all matter.

Zero Zone engineers design refrigeration systems that maximize propane’s efficiency while meeting applicable safety and regulatory requirements. Propane refrigerant is not only from refrigeration’s Genesys™—it is a practical solution that meets today’s operational and environmental demands.

Zero Zone is prepared to help you determine whether propane refrigeration is the right choice for your application. To learn more, Contact Us through our website or call to a sales representative today.